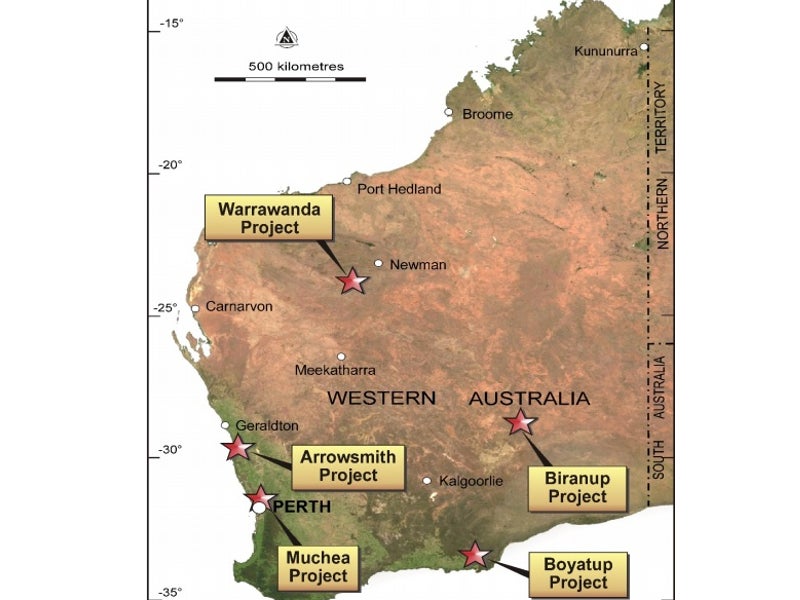

The Arrowsmith North project is a high-grade silica sand project being developed near Perth, Australia. VRX Silica is developing the project as part of the Arrowsmith silica sand projects, which also includes Arrowsmith Central and Muchea projects.

The bankable feasibility study of the project was completed in August 2019. VR Silica plans to develop the project with an initial estimated investment of A$28m ($19m).

The project is estimated to produce one million tonnes per annum (1Mtpa) of mineral sands for the first three years and at 2Mtpa through the remaining 22-year mine life. The larger Arrowsmith silica sand project is estimated to have more than 100 years of mine life.

The project will be initially constructed in two stages, with the first phase involving the construction of the processing facility and the remote feeder station.

Arrowsmith North project location, geology, and mineralisation

The Arrowsmith North project is located approximately 270km from Perth, at the juncture of Dongara and Eneabba. It is located adjacent to the Brand Highway and the Geraldton-Eneabba Railway, with a direct rail connection to Geraldton Port.

The entire Arrowsmith silica sand project area is hosted within five granted exploration licences extending more than 420km². It also comprises two pending mining lease applications.

The project hosts silica sand mineralisation within the coastal regions of the Perth Basin. The majority of the silica sand is contained in the aeolian sand dunes overlying the Pleistocene limestones and paleo-coastline.

Arrowsmith North project reserves

The project is estimated to contain JORC 2012-compliant probable ore reserves of 223 million tonnes (Mt), graded at 99.7% SiO2.

Mining and ore processing

The open-cut mining method will be utilised to extract ore at the Arrowsmith North project. The project will employ a unique and flexible mining and rehabilitation method to extract ore, maximise production and restore the rehabilitated mined areas.

The proposed mining process is to sequentially mine between 8m and 15m of sand from below the base of the soil profile in 2.25ha blocks. The plan proposes to mine up to eight blocks a year. The mined panels will be rehabilitated with intact vegetation and topsoil following extraction.

The mined silica sand will be loaded on a conventional front-end loader and delivered to a conveyor. It will be water-washed to remove any oversize and organic material. The resultant undersize silica sand will be slurried to be pumped to an off-site processing plant for beneficiation.

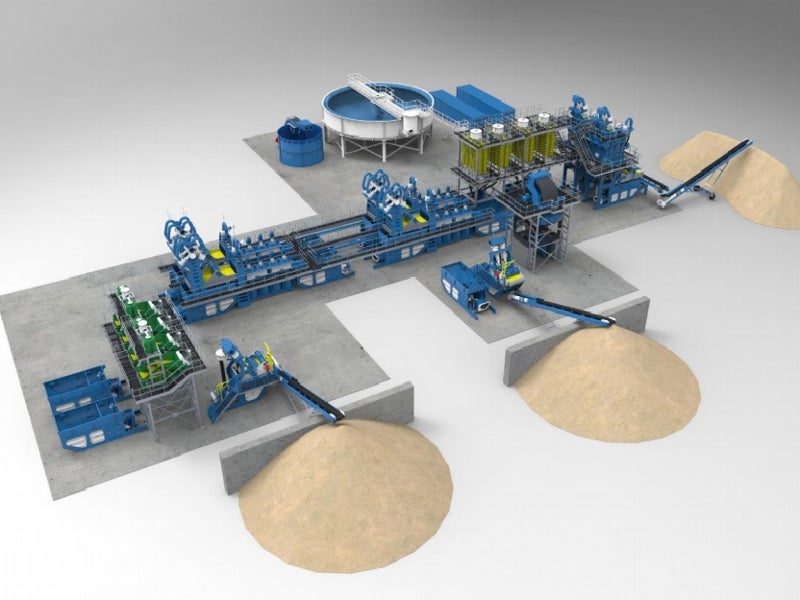

The processing plant is designed for 300 tonnes per hour (tph) throughput and will produce up to three separate silica sand products. The feeder station will take ore feed from a front-end loader, with a conveyor to transport feed to a trammel, which will screen the feed to 3mm before pumping to the processing plant.

At the processing circuit, mineral sands will pass through trammel screening and attritioning cells to remove any liberated fine particles. The resultant product will undergo spiral separation followed by magnetic separation and size screening.

The screened product will be dried and stockpiled before being transported by rail to the Geraldton Port for export to Asian glass manufacturing and foundry industries.

Infrastructure facilities

The project will be accessed by a 6km dedicated road from a junction with the adjacent Brand Highway and continued on an upgraded existing cleared track.

Fuel required for the mining operations will be stored at the fuel storage facility with a storage capacity of 55,000 litres.

Power required by the project will be provided by a dedicated diesel-fired power plant located adjacent to the processing facility.

Water will be supplied from two bores sunk to the Yarragadee North deep aquifer and piped to the storage dam at the processing plant site. Potable water requirements will be met from an off-site location. The water will be trucked to the storage tank at the mine. It will be stored in an 80m x 80m lined storage dam constructed close to the feeder station.

An additional two dams of similar size will be required to polish the processing plant return water before reusing it.

Contractors involved

CSA Global prepared the mineral resource estimates (MRE) for the Arrowsmith North project.

VRX Silica engaged local engineering company ProjX for preparing a cost estimate for the feeder, trammel, and pump station for the Arrowsmith North project.