Anglo-Norwegian mining company Norge Mining has teamed up with ABB to undertake a front-end engineering and design (FEED) study for future upstream mine production in Norway.

Earlier this year, Norge Mining discovered 70 billion tonnes of mineralised igneous phosphate rock at a new mine, known as the Bjerkreim-Sokndal Layered Intrusion site, in southern Norway.

The igneous ore comprises four critical raw minerals, namely phosphate, titanium, vanadium and subsequently phosphorus.

These four key EU-designated critical raw minerals are said to be essential for the clean energy transition and global food security.

Norge Mining and ABB will now explore the complete electrification of the Norwegian mine, which is due to be commissioned in 2028.

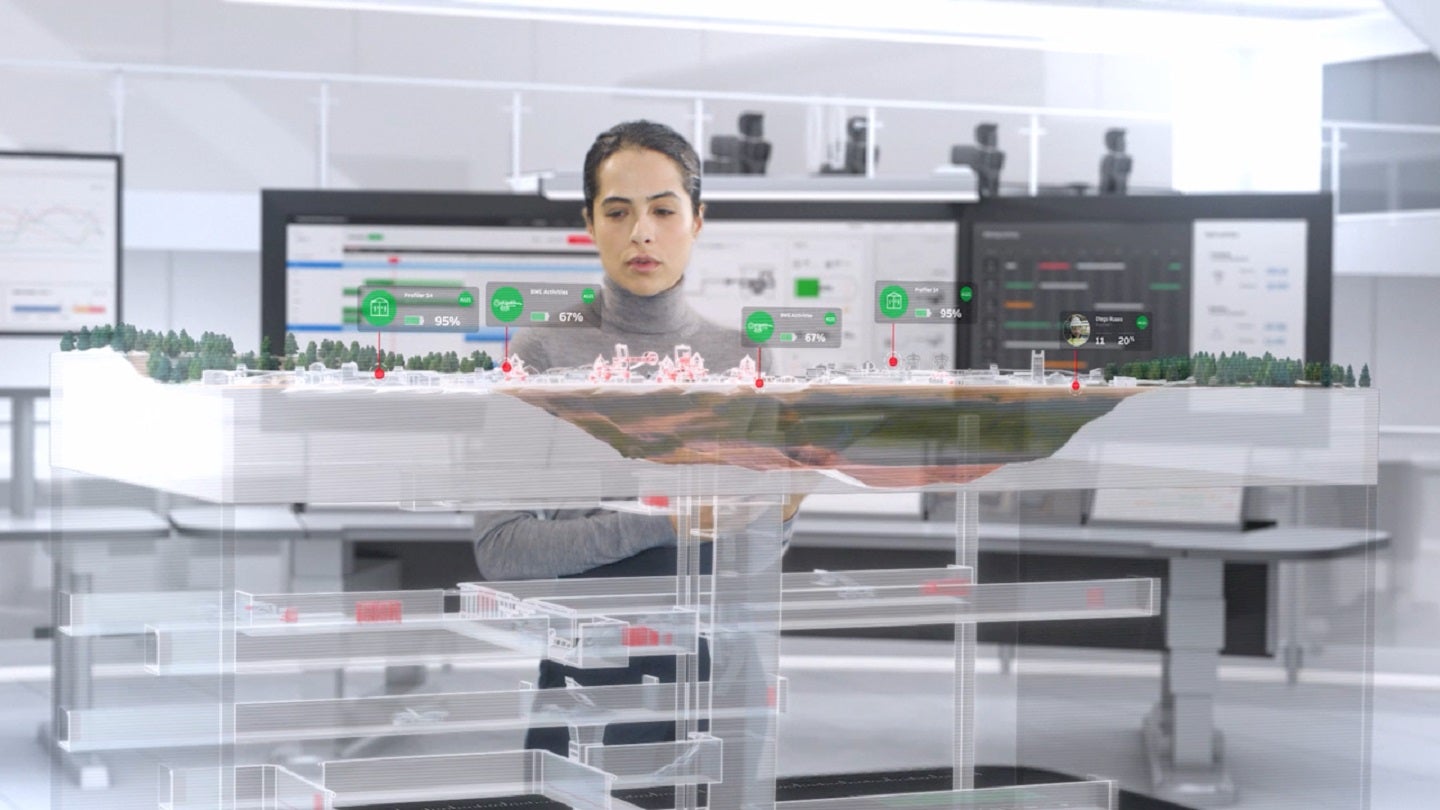

ABB will be responsible for undertaking engineering study and design electrification, automation and digital blueprint for the mine to ensure maximum sustainability, cost-efficiency and productivity.

In a press statement, ABB said: “ABB’s recommendations will also focus on low energy consumption within mine operations, as well as optimising capex and lowering opex with solutions for lower maintenance and higher efficiency.”

The Norwegian mine has the potential to meet global demand for fertiliser, electric vehicles batteries and renewable power storage for a minimum of 50 years, ABB said.

ABB Switzerland process industries cluster manager Alex Kaufmann said: “Through our early involvement, as well as our expertise in design and solutions for mining, we will support Norge Mining to optimise costs both during the construction phase as well as during the operation of the mine.

“Furthermore, our eMine approach for electrification and automation, which makes mines all-electric and includes integrated solutions that help eliminate CO₂ emissions, will help to increase the mine’s efficiency and ensure energy-efficient and seamlessly integrated systems across the entire plant.”