Mitsubishi Materials patented a method for manufacturing insert sintered parts using a forming die with fixed and movable parts. The process involves pressing a sintered part between the dies, forming a cavity, and filling it with melted material to integrate an exterior part. GlobalData’s report on Mitsubishi Materials gives a 360-degree view of the company including its patenting strategy. Buy the report here.

According to GlobalData’s company profile on Mitsubishi Materials, Ceramic membrane fuel cells was a key innovation area identified from patents. Mitsubishi Materials's grant share as of May 2024 was 38%. Grant share is based on the ratio of number of grants to total number of patents.

Method of manufacturing insert sintered parts using forming die

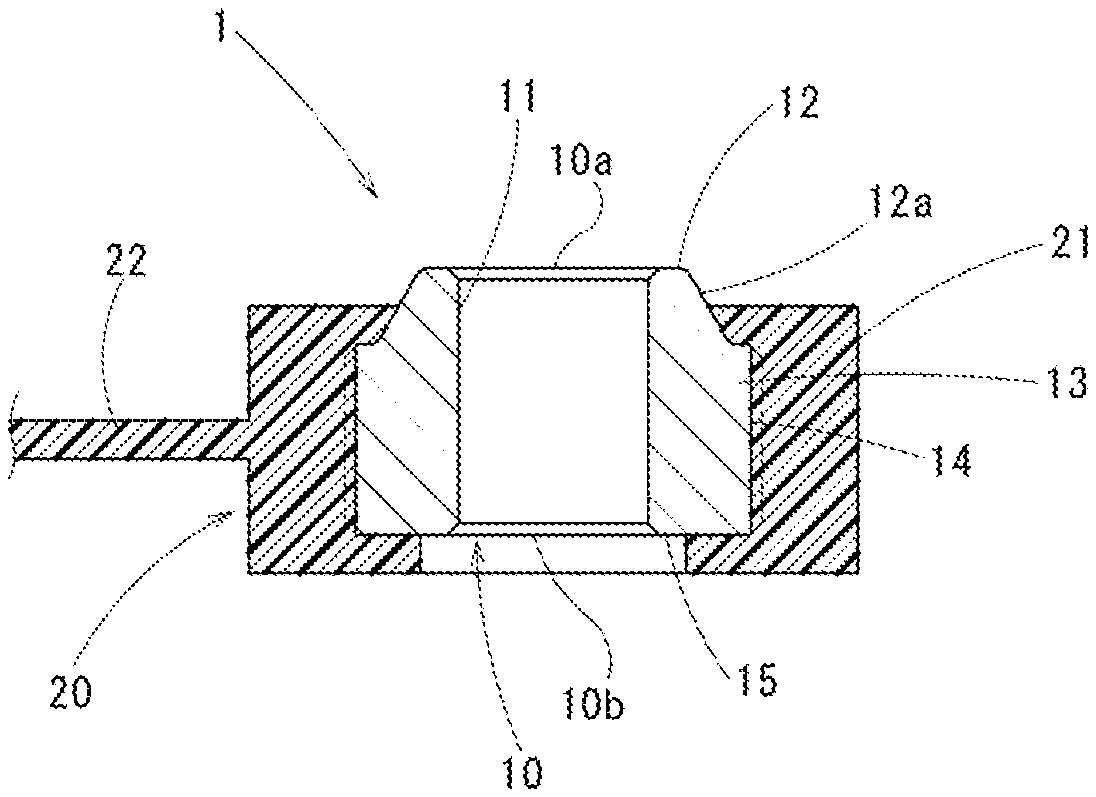

A recently granted patent (Publication Number: US11999088B2) discloses a method for manufacturing an insert sintered part. The process involves forming a sintered part with a first end part and a second end part through powder molding, followed by an insert-molding step where an exterior part is integrated into the outer peripheral part of the sintered part. The insert-molding step utilizes a forming die with a fixed die and a movable die, creating a cavity around the sintered part by pressing it against the fixed die. The cavity is then filled with melted material to form the exterior part, with the parting surface aligned along the movement direction of the movable die during the die-clamping step.

Furthermore, the patented method includes specific features such as an outer-inclined surface on the outer peripheral surface of the end parts, a concave part with a tapered surface on the fixed or movable die, and a sintered bearing with a penetrating hole. Additionally, the process involves forming an inner-inclined surface in the penetrated hole, a protruded part with a tapered surface on the die, and specific configurations for sintered bearings with penetrating holes. These innovative steps and configurations aim to enhance the manufacturing process of insert sintered parts, particularly sintered bearings with penetrating holes, by ensuring precise integration of exterior parts into the sintered structure.

To know more about GlobalData’s detailed insights on Mitsubishi Materials, buy the report here.

Data Insights

From

The gold standard of business intelligence.

Blending expert knowledge with cutting-edge technology, GlobalData’s unrivalled proprietary data will enable you to decode what’s happening in your market. You can make better informed decisions and gain a future-proof advantage over your competitors.