China Baowu Steel Group has developed an innovative induction heating system for silicon steel cores with self-adhesive coatings. Operating at a medium frequency of 6-20 KHz, the system significantly reduces processing time, enhances production efficiency, and ensures high-quality core products. The system is designed for automated operation in the production of silicon steel cores with self-adhesive coatings. GlobalData’s report on China Baowu Steel Group gives a 360-degree view of the company including its patenting strategy. Buy the report here.

According to GlobalData’s company profile on China Baowu Steel Group, AI for workflow management was a key innovation area identified from patents. China Baowu Steel Group's grant share as of March 2024 was 69%. Grant share is based on the ratio of number of grants to total number of patents.

Induction heating system for silicon steel core with self-adhesive coating

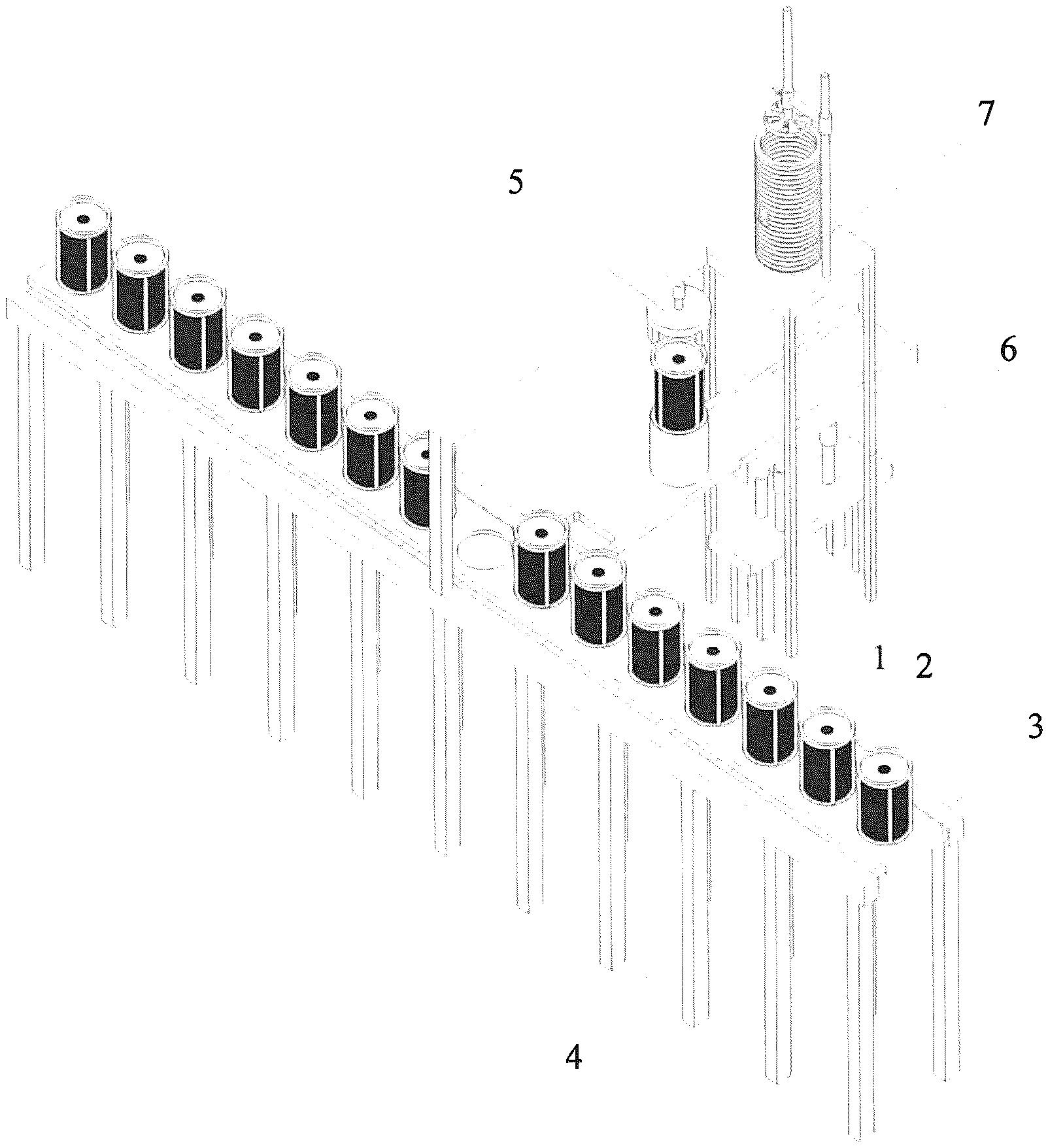

A recently granted patent (Publication Number: US11968766B2) discloses an induction heating system designed for a silicon steel core with a self-adhesive coating. The system includes a conveying roller table with stacking molds for silicon steel plates, an induction heating device with a columnar coil for medium frequency induction heating, a feeding and discharging device for horizontal movement of molds, and a loading and unloading device for vertical movement of molds under the heating coil. The loading and unloading device features a support, vertical displacement adjusting element, base plate, horizontal movable plate, and stacking mold seat for efficient handling of the molds.

Furthermore, the patent claims detail additional features such as a feeding and discharging device with a cantilever beam and manipulator, perpendicular conveying directions for roller table and feeding device, infrared temperature measuring element, pressure sensor in the stacking mold seat, and a distance measuring element for controlling vertical movement. The system also includes a compacting force adjusting element and compaction disk for applying pressure to the silicon steel plates during heating. An induction heating method utilizing this system involves compacting the plates, conducting induction heating at a medium frequency of 6-20 KHz, real-time temperature measurement, and stopping heating once the plates reach the desired temperature. This innovative system and method aim to enhance the efficiency and precision of induction heating processes for silicon steel cores with self-adhesive coatings.

To know more about GlobalData’s detailed insights on China Baowu Steel Group, buy the report here.

Data Insights

From

The gold standard of business intelligence.

Blending expert knowledge with cutting-edge technology, GlobalData’s unrivalled proprietary data will enable you to decode what’s happening in your market. You can make better informed decisions and gain a future-proof advantage over your competitors.