The Gediktepe project is a polymetallic site being developed in Balikesir province of western Turkey.

Polimetal Mining Industry and Trade (Polimetal Madencilik), a 50-50 joint venture of Lidya Madencilik (Lidya) and Alice Gold (Alacer), is developing the project.

The pre-feasibility study (PFS) of the Gediktepe project was completed in September 2016 and further updated in April 2019.

The mine is expected to produce 345,000oz of gold and 8.15Moz of silver through its estimated mine life of 11 years. The total production also includes 387,000t of copper concentrate and 503,000t of zinc concentrate.

Gediktepe project location, geology, and mineralisation

The Gediktepe project is located approximately 370km from Ankara and 190km from Istanbul. The metamorphics present at the project majorly host gneiss, schists, phyllite, amphibolite, marble, and quartzite.

Gediktepe is identified as a sulphide deposit contained within metamorphic schist units, with sphalerite and chalcopyrite being the major economic minerals. The upper portions of the mine have undergone weathering, leaching, and oxidation processes by naturally occurring acidic surface water and groundwater.

The oxide zone of the project does not contain any base metals, but gold and silver remain relatively intact while the sulphide zone contains zinc, copper, gold, and silver.

Most of the mineralisation is hosted within the Chlorite-Sericite Schist, which has gone through metamorphosis under green schist facies conditions.

Gediktepe project reserves

The project is estimated to contain proven and probable oxide ore reserves of 2.76Mt, grading 2.34g/t Au and 56.7g/t Ag. The sulphide proven and probable reserves are estimated to be 18.6Mt grading 0.85g/t Au, 31.8g/t Ag, 0.92% Cu, and 1.98% Zn.

The Gediktepe deposit is estimated to contain 207,000oz of gold and 5.02Moz of silver within the oxide ore. The contained metal within the sulphide ore includes 509,000oz of gold, 19.008Moz of silver, 170,000t of copper, and 368,000t of zinc.

Mining and ore processing at Gediktepe

The conventional open-pit mining method, involving excavators and trucks, will be applied to extract oxide and sulphide ore from the Gediktepe polymetallic mine.

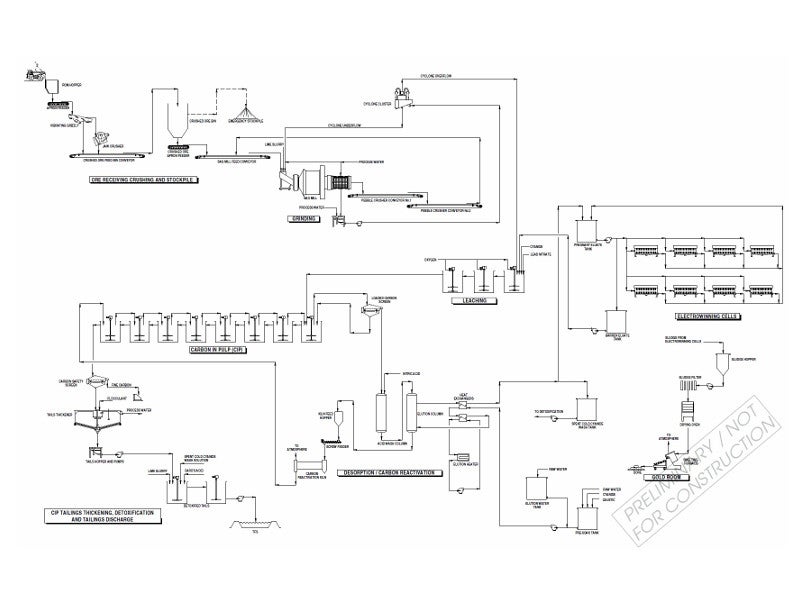

The oxide ore is proposed to be processed for the first two years in a carbon-in-pulp (CIP) plant, at a rate of 1.1Mtpa. It will be processed by tank leaching and use a single-stage semi-autogenous grinding mill (SAG) circuit followed by a carbon in pulp (CIP) gold circuit.

Gold and silver from the tank leach process will be produced in the form of doré and sent to refiners for separation. The polymetallic sulphide ore will be processed in a concentrator operating at a rate of 2.4Mtpa.

A secondary grinding ball mill will be added to the oxide grinding circuit for processing sulphide ore from the third year. The product will pass through two, four-stage flotation circuits in a sequential order to produce separate export-quality copper and zinc concentrates.

Infrastructure facilities

Major infrastructure facilities supporting the project will include administration buildings and facilities, water diversion and storage facilities, heap leach facility, and a waste storage and tailing facility.

Workers will be recruited from the nearby villages or transported from Bigadic and a temporary construction camp will be installed to accommodate them.

Contractors involved

AMC Consultants updated the mineral resources of the Gediktepe project in mid-2018 while OreWin was engaged for conducting a full review of the mineral resource estimate.

GR Engineering Services is participating in the preparation of Gediktepe project’s definitive feasibility study.

Consultants from Resource Development, SRK Consulting (US), and Independent Mining Consultants prepared the PFS. SRK conducted hydrogeological, hydrological, geotechnical, and waste geochemistry studies as part of the environmental impact assessment (EIA) and the PFS of the Gediktepe project.