The Kharmagtai high-grade open-pit copper-gold project is under development in the Omnogovi province of Mongolia.

The project is owned by Zijin, a global mining company, and Xanadu Mines, a Mongolia-based exploration company.

The scoping study of the project was completed in April 2022. The pre-feasibility study commenced in 2023 and is expected to be completed in the third quarter of 2024.

The final investment decision on the project is expected to be taken in 2024. Onsite construction at the project is expected to commence in 2026.

The Kharmagtai copper-gold project is expected to achieve first production by the end of 2027. It is estimated to have an average annual production of 50,000 tonnes (t) of copper and 110,000 ounces (oz) of gold over a life of mine (LOM) of 30 years.

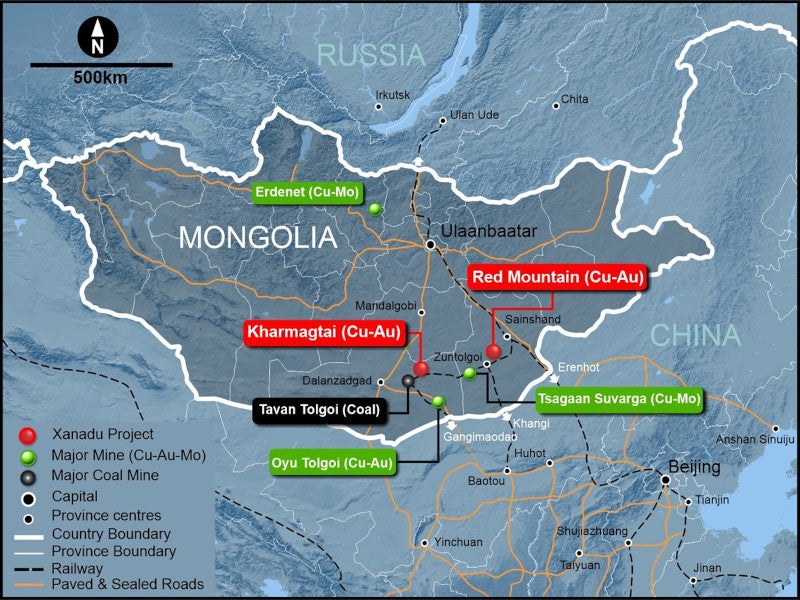

Kharmagtai copper-gold project location

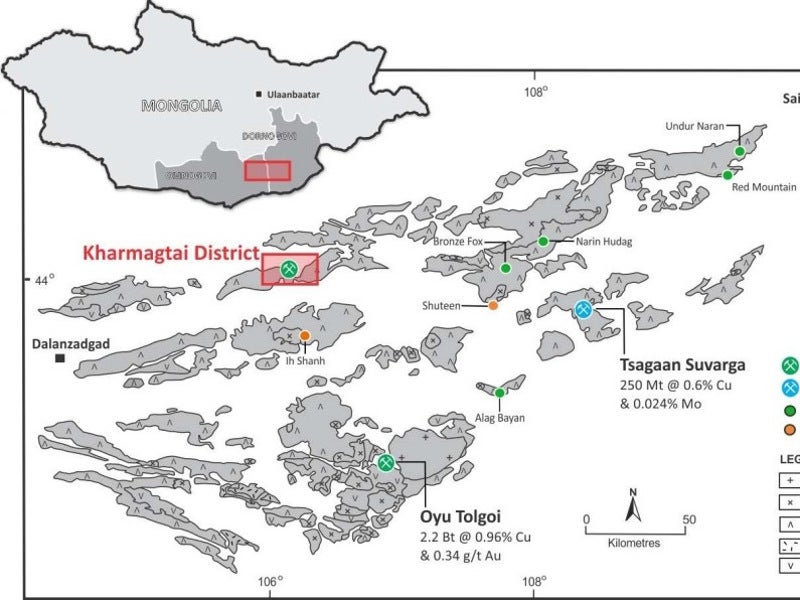

The Kharmagtai copper-gold property is located 420km south-southwest of Ulaanbaatar town and 60km from the regional centre of Tsog Tsetsii.

The property lies approximately 120km north of Rio Tinto’s Oyu Tolgoi copper-gold mine.

The project is a part of the South Gobi porphyry copper province, which hosts major porphyry deposits, including Oyu Tolgoi, Tsagaan Suvarga and the Oyut Ulaan porphyry copper-gold exploration project.

Geology and mineralisation

Kharmagtai comprises multiple co-genetic, gold-rich porphyry copper centres and tourmaline breccia pipes situated within the Carboniferous Kharmagtai Igneous Complex. The complex is characterised by a series of intrusive bodies with compositions ranging from diorite to monzodiorite, quartz-monzodiorite, monzonite and granodiorite.

Mineralisation at Kharmagtai occurs in three distinct styles: porphyry-style stockwork Cu-Au mineralisation, tourmaline breccia-style Cu-Au mineralisation and epithermal gold associated with carbonate base metal veins.

Kharmagtai copper-gold project reserves

The Kharmagtai copper-gold project is estimated to hold 47.5 million tonnes (Mt) of indicated resources, grading 0.23% copper and 0.22g/t gold, as of March 2023. The contained metal is estimated at 110,000t of copper and 332,000oz of gold.

Inferred resources are estimated to be 4.5Mt, grading 0.19% copper and 0.19g/t gold and containing 9,000t of copper and 28,000oz of gold.

Mining at Kharmagtai copper-gold project

The Kharmagtai copper-gold project will be developed using a conventional open pit mining method following a standard drill, blast, load and haul cycle.

The open pit mine is projected to have a favourable strip ratio of 0.9:1 for the initial five years, followed by a slightly higher ratio of 1.1:1 over the life of the mine of 30 years.

The mine’s development will occur in two stages. The first stage will have a capacity of 15 million tonnes per annum (Mtpa), which will be expanded to 30Mtpa in Stage Two.

The mining site will encompass open pits at several deposits, including Stockwork Hill, White Hill, Copper Hill, Zephyr and Golden Eagle. The majority of the mineral resource is located within the White Hill and Stockwork Hill deposits, which are anticipated to amalgamate into a single large super-pit.

There are also plans to develop the mine as an underground mine.

Ore processing

The run-of-mine (ROM) ore will undergo crushing in a primary gyratory crusher equipped with a 750kW motor. The crushed ore is then discharged onto a stockpile with a 20-hour live capacity.

The grinding circuit will consist of a semi-autogenous grinding mill with a 20MW motor, two MP1000 recycle crushers, and a ball mill, with a 20MW motor, operating in a closed circuit.

The grinding circuit will include two stages of flash flotation, from which coarse gold will be extracted. The gold will then be smelted to produce dore bars. The residual material from the flash flotation concentrate will be directed to the final concentrate.

Leaching of the ore will be undertaken in three stages, starting with an acid leach to remove cyanide-soluble copper, followed by GlyCat™ glycine leach, licensed from Draslovka Mining Process Solutions (DMPS), a chemical technologies, products and services company. The process will neutralise acid, and finish with a cyanide leach to recover gold and silver.

The flotation circuit will encompass roughers, rougher scavengers, regrind mills, cleaners and cleaner scavengers. The circuit will be accommodated within an insulated, heated shed to ensure optimal operating conditions. The flotation concentrate will be thickened, filtered and placed into containers for transportation to smelters.

The tailings will be thickened and transported to the tailings storage facility and will then be transported to smelters by rail.

Site infrastructure

The site is situated 10km north of a sealed road from Tsogtsetsii and has a 416km railway line that links Tavan Tolgoi with the Trans-Siberian railway at Sainshand. A mine access road will be constructed to connect with this road and railway. This will enable the transportation of copper-gold concentrates from an existing rail siding, located 15km off the site.

The estimated power requirement for the site’s initial operation is 55MW and is set to double to 110MW as operations expand to 30Mtpa. Power will initially be supplied via a connection to the existing 32kV line at Manlai, later transitioning to a new 110kV line from Tavan Tolgoi.

Water for the site will be sourced from a water resource located 8km from Kharmagtai, established by Rio Tinto as part of the Kharmagtai mining licence application. The water will be pumped to the site through a pipeline. A water purification plant will supply potable water.

Contractors involved

CSA Global prepared the scoping study of the Kharmagtai copper-gold project with support from O2 Mining and Xanadu Mines.