Propeller has distinguished itself in the mining industry with its innovative geospatial solutions, winning two awards in the 2025 Mining Technology Excellence Awards in the Innovation and Safety categories.

The Mining Technology Excellence Awards honor the most significant achievements and innovations in the mining industry. Powered by GlobalData’s business intelligence, the Awards recognize the people and companies leading change and shaping the future of the industry.

Propeller won the Innovation award for its groundbreaking map-based solutions that have transformed data capture, analysis and management processes in mining operations. It received the Safety award for its advanced remote monitoring solutions that significantly enhance on-site safety by reducing human-machine interactions and improving hazard identification.

Innovative geospatial solutions for mining

By integrating geospatial data from various data capture tools, ranging from drones and machine mapping to GPS rovers and handheld scanners– Propeller’s platform delivers survey-grade results with unprecedented efficiency and cost-effectiveness. This transformation is evident in the introduction of AeroPoints, the only smart ground control points designed to make high-accuracy surveying accessible and affordable for mines and quarries worldwide. AeroPoints are user-friendly, featuring solar panels, batteries, GPS, and WiFi capabilities, which simplify the setup process and reduce the need for extensive training.

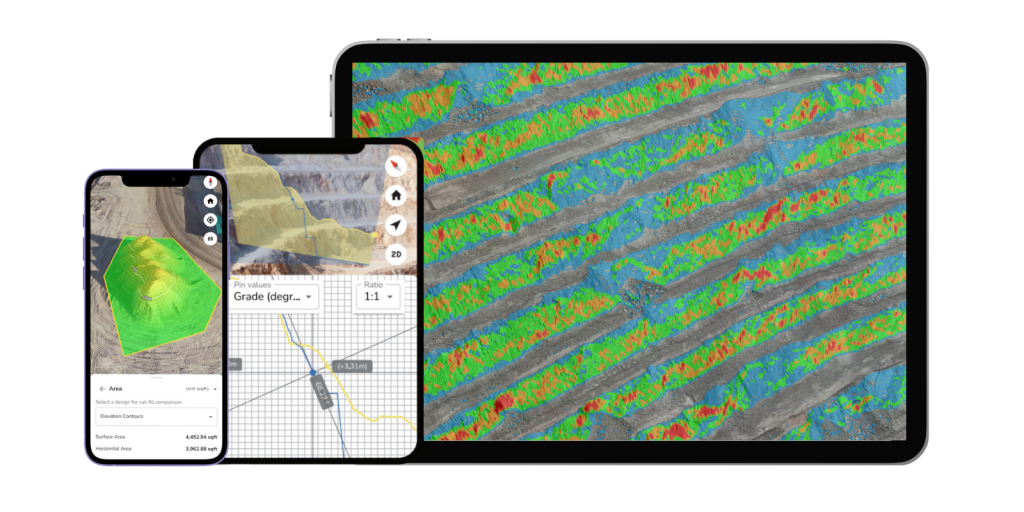

The company’s end-to-end workflow deliver interactive 3D maps that bring people, mine plans, and survey data together with one unified view, enhancing decision-making and productivity across mining operations. Propeller’s platform supports multiple data formats and systems, ensuring seamless integration with existing workflows and enhancing operational flexibility. For instance, the platform’s compatibility with Trimble and Topcon calibrations allows for easy adoption by sites already using these systems. Additionally, Propeller continuously innovates in geospatial data processing, utilizing automated ground control point (GCP) recognition with machine learning to streamline the creation of accurate 3D models and orthophotos. This capability reduces the time and expertise required to produce high-quality maps, enabling project teams to focus on strategic decision-making rather than data processing.

The comprehensive geospatial data analytics and management capability of Propeller’s platform empowers users to map, measure, and manage their sites with ease. Users can perform tasks such as calculating stockpile volumes, visualizing blast plans, and analyzing slopes directly from the platform, which leads to smarter workflows and higher margins. The platform’s ability to process multiple flights simultaneously and provide proactive QA/QC checks ensures that data is both accurate and reliable, further enhancing operational efficiency.

Enhancing mining safety with remote monitoring solutions

Propeller’s commitment to safety is evident in its remote monitoring solutions, which have significantly enhanced on-site safety by minimizing human-machine interactions. The company’s high-resolution imagery and detailed 3D models enable frequent remote inspections from the safety of an office, reducing the need for personnel to enter potentially hazardous areas. This capability not only improves safety, but also contributes to more precise blast planning and hazard identification, reducing the risk of accidents. For example, detailed 3D models of blast areas allow engineers to plan with precision, ensuring that blasts are conducted safely and efficiently.

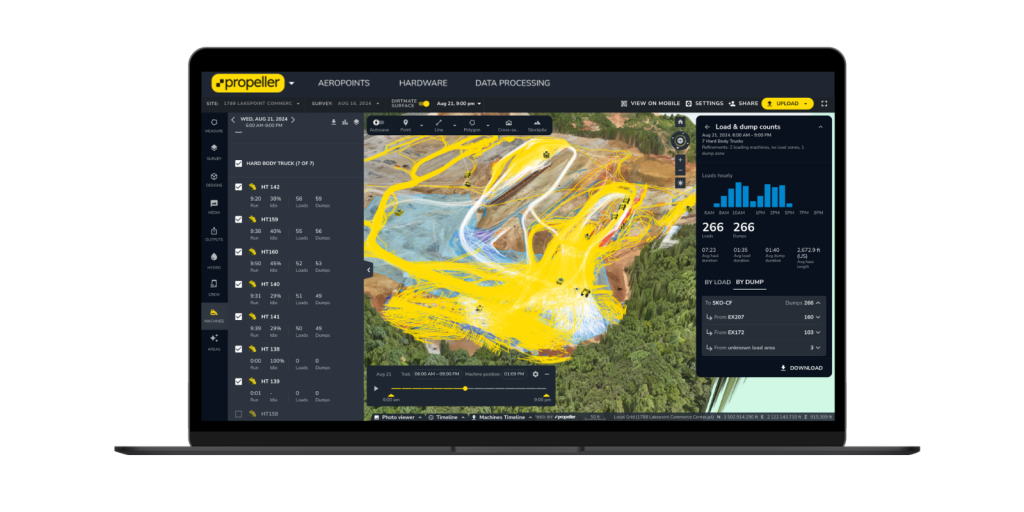

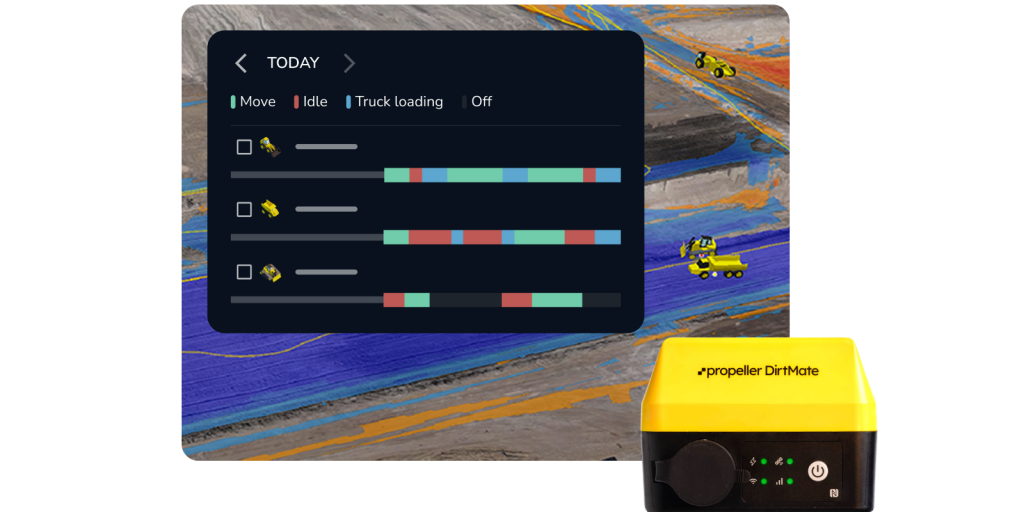

Propeller’s solutions, such as DirtMate, provide real-time remote monitoring insights, ensuring compliance with safety standards and reducing the likelihood of incidents. DirtMate, a universal GNSS and telematics system, , offers insights into machine utilization and operator efficiency , allowing for more productive and proactive management of on-site operations. The company’s accurate site maps, combined with real-time haul metrics, improve traffic and road safety management, helping to reduce cycle times and vehicle wear, thereby promoting a safer work environment. By providing live site maps, Propeller enables teams to optimize traffic plans and maintain consistent road grades, which are crucial for safe and efficient transportation within mining sites.

Additionally, Propeller’s remote monitoring features facilitate better environmental compliance and safety by tracking site changes, marking no-go zones, and monitoring waste dumps and tailings dams. These features help avoid environmental fines and ensure regulatory conformance by providing a visual timeline of site changes and proof of regulatory compliance. The ability to monitor sediment flow and adjust fill rates in waste dumps and tailings dams further enhances environmental safety, ensuring that mining operations remain sustainable and compliant with environmental regulations.

“As a former mine surveyor and engineer, it’s exciting to be part of Propeller’s impact on the mining industry. As a collaborative hub for geospatial data, we’re seeing more and more teams adopt cloud-based tools to streamline their workflows. We’re particularly looking forward to showcasing our innovative solutions—like DirtMate, which provides automated cycle, load, and dump counts. Our goal is to bridge the gap between the office and the field with cross-functional data anyone can access, anytime.“

– Kevin Smith, APAC Regional Sales Manager, Propeller

Company Profile

Propeller’s map-based command center gives site managers the power to make the complex simple. By bringing survey data, design files, and machine tracking into one visual platform, we enable teams to verify work, track progress, and collaborate in real time.

Mining professionals trust Propeller to prevent costly mistakes, optimize resources, and maintain compliance through easy-to-understand visuals that anyone can use—no technical expertise required. Survey and operations teams stay perfectly aligned, communication barriers disappear, and production stays on schedule and within budget with accurate inventory tracking and site progress documentation.

One map means one team. It’s a one-stop hub for communication and transparency between teams and businesses. And, with just a few clicks, project teams access critical insights that make their jobs simpler, faster, and smarter. Revolutionizing the way they work, from the ground up.

Contact Details

Kevin Smith, APAC Regional Sales Manager

E-mail: kevin@propelleraero.com.au

Phone: 0408 226 551

Links