Challenger Gold has advanced towards mining and toll milling at its Hualilan project in San Juan province, Argentina, following the execution of key mining contracts and a toll milling agreement.

The company has finalised open-pit mine designs and schedules for the initial toll milling pits, while also progressing with the necessary operational expenditure and capital expenditure models.

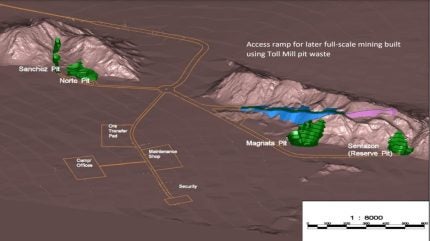

The initial plan to develop four small toll milling pits has been revised. After optimisation studies and strategic assessments, it was decided that only three pits – Sanchez, Norte, and Magnata – would be necessary to meet the toll milling objectives.

The Sentazon pit has been kept in reserve, allowing for operational flexibility and potential additional toll milling if needed.

The selected pits have a total mineralised material of 450,000 tonnes (t), with an average grade of 6.7 grams per tonne (g/t) of gold and 39.7g/t of silver, containing 97,200oz of gold and 575,000oz of silver.

The final mining schedule for tolling highlights an improved outcome, with a 10% grade increase, containing 92,500oz of gold and 548,000oz of silver.

The first three months of mining are set to deliver six months of toll milling feed of more than 90,000t of toll milling material. It will have the initial 150,000t of material averaging 8.7g/t of gold and 34.5g/t of silver.

The completion of the mining schedule enables the finalisation of contract mining and haulage contracts for the toll material.

The toll milling pre-feasibility study (PFS) is being prepared in accordance with JORC and Canadian NI 43-101 standards, with completion scheduled for March 2025.

The project was the first gold mine in 17 years to secure environmental impact assessment approval in the province in October 2024.

Challenger Gold managing director Kris Knauer said: “The completion of toll milling pit design and mining schedules is a significant milestone as it allows us to finalise quotes for contract mining and trucking of material to Casposo.

“Finally, Austral Gold, the toll mill operator, has indicated that refurbishment of the Casposo Plant is progressing.”

Whittle Consulting has conducted an optimisation of the toll milling pits as part of the broader enterprise optimisation study for the stand-alone Hualilan full-scale study, which is nearing completion.