Pick, place, press, twist, connect – these are the defining actions of an AI robot workforce said to be able to carry out work that would otherwise done by humans for the first time.

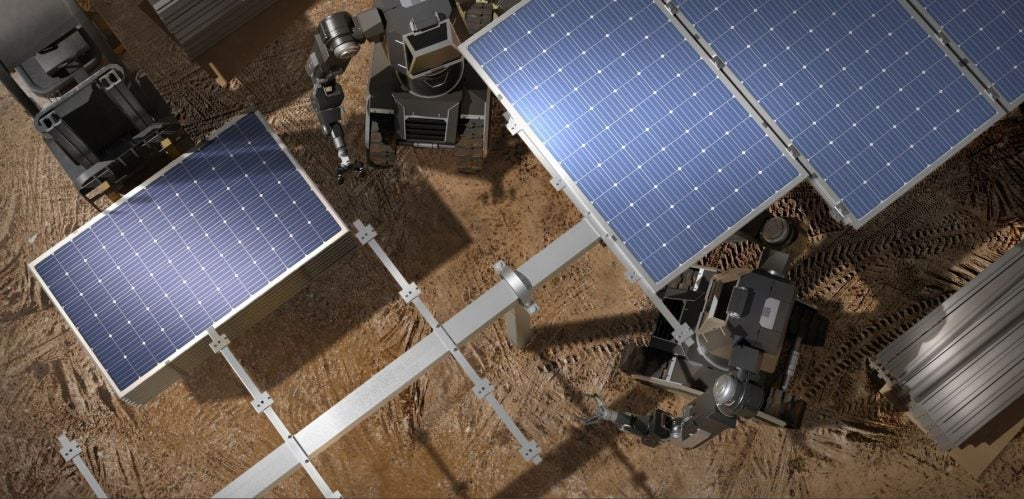

RoboForce, the start-up behind the RF-04 robots, says it is “building the world’s most advanced robo-labour system”. Built on the five capabilities of mobility, manipulation, learning, communication and safety compliance, the robots are intended for use across the solar, space, manufacturing and mining industries, among others.

The company’s founder and CEO Leo Ma tells Mining Technology: “There’s a long list of things that new-generation AI-robotic systems can do – picking up bananas or apples, folding T-shirts, cooking and all of that. At RoboForce, we don’t do any of that. We have a very clear focus on robo-labour.”

The company is ostensibly attempting to address labour shortages for “the most tedious, physically demanding and dangerous jobs that humans shouldn’t have to do”, although talk of robot workers naturally raises questions about where that leaves their human counterparts.

“We view our robotic workforce solution not as a job replacer but as a job enabler,” says Veeral Hardev, head of business development at RoboForce, to Mining Technology. “Our technology will allow human workers to transition to safer, less hazardous roles, enhancing overall workplace safety and productivity.”

The extent to which such a transition might happen, of course, depends on whether any given company would actually want to redeploy their human workers having taken care of their previous roles robotically – and how much of its human resources budget would be reallocated for robot resources in that scenario.

US Tariffs are shifting - will you react or anticipate?

Don’t let policy changes catch you off guard. Stay proactive with real-time data and expert analysis.

By GlobalDataHardev says the plan is for RoboForce to lease its robots with ongoing technical support and maintenance and that pricing will be set per robot, “delivering over 50% cost savings compared to current labour expenses, as our robotic workforce is three times more efficient and productive than human labour”.

Time will tell how accurate that claim proves to be, but there are indisputable benefits in taking humans out of dangerous environments. As GlobalData’s Robotics in Mining report states: “Robotics and automation are improving safety in mines. Using robots removes human workers from physical, biological and ergonomic hazards. Robots also excel in tasks like drilling in narrow or dangerous areas like unstable rock formations, while autonomous haulage systems significantly decrease the risk of accidents.”

Robo-labour for mining

On this point, and in relation to the mining sector specifically, Hardev says: “The challenges that the workers have from a physical standpoint – the fatigue and the danger, especially, that exists – that’s really where we see the opportunity and the value proposition. Our solution is the worker. It’s not like the other industrial heavy machinery tools that are clearing earth and doing those kind of things. You still need people that go into the mine, if you will.

“That’s what we are targeting. We’re targeting to be able to do the same work that those workers are actually manually doing so we can remove them and alleviate the pressure that they have and the danger, especially, that they are surrounded with.”

The mining applications RoboForce envisages for its robots – mine construction, excavation and logistics support – are all certainly areas that pose inherent risk, but to what extent can such complex tasks realistically be carried out by robots? Ma contends that this is the wrong way to look at the challenge.

“Think about a worker’s work both in mining and beyond that application,” he says. “Pick up anything that is needed, place anywhere as the target position, understand and press any button, twist and connect any objects. This is what we are working on – it’s very different from what you may have thought about – this is the robo-labour primitive capability from the model.

“We cannot think of any worker’s work in a wider range of applications that goes beyond pick, place, press, twist and connect. So, we train the model to do that very well, and then we project into mining.”

In those terms, it all sounds very simple, but putting this into practice in a working mine is a challenge of a different order. Ma and Hardev believe that the people involved in RoboForce are uniquely placed to overcome it.

RoboForce funding and team

Freshly out of stealth mode, the company announced at the start of January that it had raised $10m in early-stage funding from the likes of Nobel Laureate Myron Scholes, the well-regarded tech venture capitalist Gary Rieschel and Carnegie Mellon University.

Indeed, Carnegie Mellon alumni feature prominently on its team alongside others from institutions including Michigan Robotics and companies like Amazon Robotics, Apple, Google, Microsoft, Tesla and Waymo. Ma considers RoboForce to have “a two-to-three-standard-deviation-outlier-level” team, combining “the best schools, the best company experience, the best project experience”.

“We have more than 100 years’ experience building this,” he says. “So, what went well and what went wrong in the previous many years, that level of technical depth gives us a solid foundation of making technical and architectural decisions for both AI and robots.”

Putting this into the context of what RoboForce is hoping to achieve through the marriage of AI and robotics, Hardev says: “We’re able to accelerate that kind of activity just because of all the experience. It’s not like, I think, any team can do this in the world. It’s this unique collection of all these different experiences, that’s really what’s behind it.”

What this team has given RoboForce is the expertise to create AI-driven robots with accuracy levels of 1mm for performing fine motor movements by both the hardware itself and the model that powers it, which Ma says the company was the first to achieve.

RoboForce also develops both its AI and robotics in-house, which naturally has its own benefits, with greater opportunities for joined-up thinking, collaboration and iteration.

Hardev believes that scaling its team is one of RoboForce’s biggest challenges alongside deploying its robots. For the latter, successful pilot projects need to be completed before commercial deployments begin.

Of course, given the high-tech, high-cost nature of the business, there are any number of other potential pitfalls that could put paid to RoboForce as it grows, but the contention that the company – and others like it – might help to solve labour shortages is not without merit.

The future of the AI robot workforce

GlobalData’s Robotics in Mining report explains: “The mining industry faces a severe labour shortage. This was exacerbated by the Covid-19 pandemic when travel restrictions hit every sector and mining companies had to rely on offshore workers to fill vacancies. This established a chain effect that led to a further lack of skilled workers.

“Recent public failures in the industry relating to safety, the destruction of indigenous cultural sites and workplace culture have all negatively impacted the attractiveness of working for a mining company.”

It also points to a 2023 McKinsey survey in which 71% of mining leaders stated that talent shortage was hampering them from delivering targets.

“There are many things for the economic system that we need that demand work that is tedious, force-demanding and dangerous, and we think there are things that shouldn’t have to have a human to do them,” says Ma. “As of today, globally, there’s a huge supply shortage, and there’s a huge demand. In that kind of work, the gap is not getting getting closer. It is actually getting bigger.”

He adds: “Also, once this goes broader, there will be a change-propagating effect as the productivity really goes up… I don’t see it as a 2% or 3% increase. It is a significant enabler for things that humans shouldn’t have to do – and then multiples of that. Think about if a solar centre was scheduled to be built by several hundred people for ten years. Now, we can have 4,000 robo-labour workers build it for one year.”

In terms of the number of robot workers that the company will actually roll out for clients, Ma confirms that one early-stage solar partner is indeed looking at the possibility of thousands of units.

With the potential for robot workers to be more productive and deployed in greater numbers in mind, Ma suggests that the timescales for major mining projects could be similarly reduced in the long term using robo-labour.

However, while the value of using robots for tasks that may not be suited to humans seems reasonable, talk of their evolving capabilities still raises the question of what may happen further down the line when they become simply the better option for any given job.

Considering the prospect that robot workers in the future will be able to carry out tasks to a higher level than humans, Hardev says: “The robot is not going to get tired. It’s not going to get fatigued. It’s not going to take breaks. It’s eventually going to be more capable and powerful than a human worker would be, whether that’s strength or whether that’s just doing other physical things.

“So, yeah, we definitely think it will go beyond what a human is capable of doing, but we’re not promising that quite yet. We just see that as an evolution and advancement of the technology over time.”

Next steps for RoboForce

For now, though, RoboForce is focused on making the leap from start-up to scale-up and establishing itself as a viable business, with a view to rolling out dozens of robots this year, hundreds by 2026 and thousands by 2027.

“We are graduating from sales mode, continuing building the new iteration of our learning model and our new iteration of robot, and we’re putting it into our product,” says Ma.

Hardev adds: “I look at this growth stage as the commercialisation stage. This year, we’re going to do our first projects with paid customers. We will increase the productivity level over the rest of this year with each subsequent project, and then, around the end of this year to the beginning of next year, you could consider it being our full commercial launch. That is, more specifically, just in the solar industry.”

In the mining sector, RoboForce has engaged with industry leaders to explore the potential applications of its robot workforce. It is also said to be in early conversations with a prospective customer in the sector. Despite this, it is early days, and Hardev predicts that a fully formed offer for mining is around three to five years out.

“Currently, we are focused on our initial applications in the solar industry and anticipate launching our first products this year,” he explains. “Following this, we plan to expand into other markets and applications, including mining.”

By then, of course, the technology will have progressed further.

“The speed of the advancement of the technology, it’s kind of hard to describe,” says Hardev.