Concrete spraying, or shotcrete, is a core method for reinforcing underground mining and tunnelling projects. This process projects a concrete mix at high speed onto rock surfaces, creating a robust support layer essential for stability and safety. However, concrete spraying is both challenging and resource-intensive, with overspray, rebound, and underspray posing risks to both project efficiency and safety. Next-generation solutions are required to meet efficiency, safety and sustainability requirements at a cost that is acceptable to an industry operating in a constrained macroeconomic environment.

Finland-based Normet, an innovator in mining, tunnelling and construction technology, believes it is setting new standards in this area.

Cost-efficient and sustainable – not mutually exclusive

“Precision in layer thickness is critical in concrete spraying. Excess material, often applied to avoid the risk of underspraying, leads to waste and drives up project costs. Traditional methods, relying on visual judgement and manual probing, make it difficult to ensure consistent coverage without some degree of over-application,” says Panu Oikkonen, director of underground process excellence at Normet, which launched its SmartScan measurement system in 2019.

“By capturing and analysing detailed data during spraying, SmartScan provides a path toward more sustainable, cost-effective underground operations.”

The Normet SmartScan delivers a new level of accuracy to sprayed concrete layer thickness information for the sprayer operator and easy reporting for management, lowering the environmental effects of a very carbon-intensive process.

Certain concrete mixes produce between 450–500 kg of CO₂ per cubic metre, so reducing unnecessary usage is both a financial and environmental priority. Concrete wastage, particularly from overspray, rebound, and overlap, has historically been difficult to control. SmartScan combined with spraying process data analytics can address these issues by targeting specific wastage categories and enabling precise application that minimises excess.

By using laser scanning to measure tunnel surfaces before and after spraying, SmartScan calculates layer thickness with pinpoint accuracy. This real-time feedback allows operators to check that target thicknesses are achieved without the need for extra material. The visualisation provided by SmartScan gives a detailed view of each layer, reducing the guesswork inherent in traditional methods and enabling a much closer match to design specifications.

Oikkonen says this capability is “transformative”, as overspray and other types of waste can add substantially to a project’s material consumption and carbon footprint. “The efficiency gained from SmartScan represents a win for both project economics and environmental sustainability, but also worker safety.

“The risks of underspraying, where concrete application falls short of design specifications, can be severe, compromising structural integrity and safety. Traditionally, the approach has been to overspray to reduce the risk of underspraying, but this practice leads to excess material use and increases the environmental impact of the project. SmartScan helps to create structurally sound layers while optimising material use.

Automating documentation and compliance

Part of Normet’s total performance solutions package, which provides customers with industry-leading equipment, digitalised optimisation software, and Normet expertise, SmartScan transforms the documentation process, a critical aspect of large-scale infrastructure projects that often involves significant manual labour and post-application inspections. For instance, the E39 Rogfast project in Norway—set to be the world’s longest and deepest subsea tunnel—uses Normet’s SmartScan to ensure precise sprayed concrete applications while automating the documentation process. Hæhre Entreprenør AS, the contracting firm on the Rogfast project, mounted SmartScan on spray rigs to capture pre- and post-spray profiles, generating georeferenced maps of the sprayed layer thickness. This setup provides comprehensive documentation that meets Norway’s rigorous regulatory standards while minimising the need for manual inspections and adjustments.

By eliminating much of the manual measurement work, Hæhre Entreprenør was able to ensure quality and consistency across the project while also meeting strict environmental and reporting requirements.

The SmartScan system allows contractors to document as-built data immediately after application, fulfilling stringent requirements for accuracy and safety. This near-instantaneous reporting capability simplifies compliance and reduces the labour needed for post-spray assessments, freeing up personnel to focus on other critical areas of the project.

Building a digital ecosystem in concrete spraying

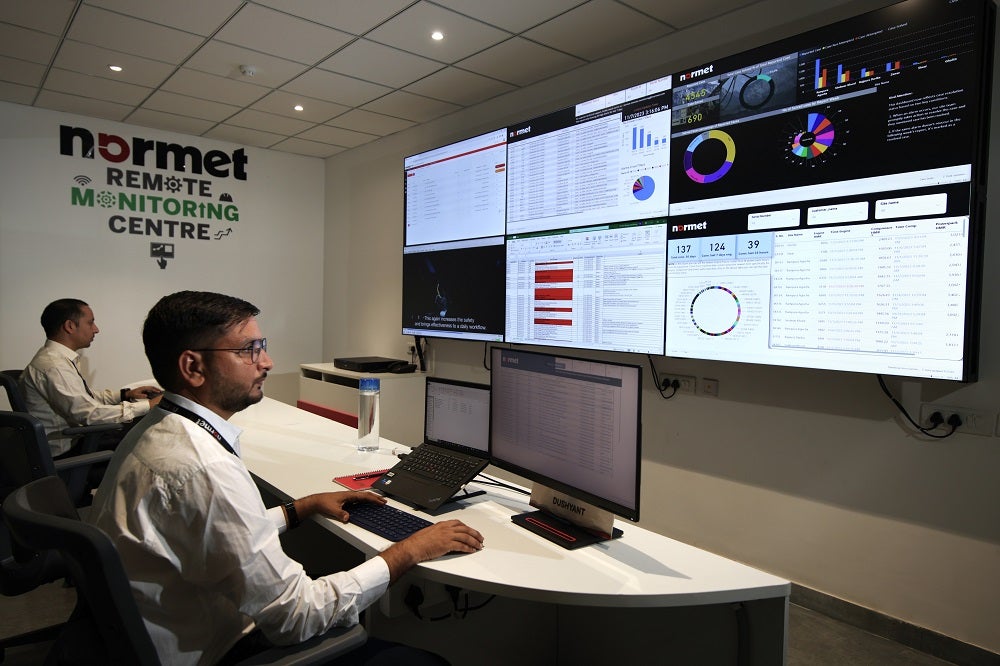

According to Oikkonen: “We’re creating a digital ecosystem around the entire spraying process, including process data and machine automation.” This ecosystem integrates data sources, including process metrics and machine performance, providing insight that will lead to further optimised spraying applications.

Incorporating Building Information Modelling (BIM) techniques into underground projects will be a next step for Normet in advancing this digital ecosystem. BIM, which is already widely used in above-ground construction, could transform underground workflows by enabling more accurate and comprehensive project planning, execution, and monitoring. While challenges such as the lack of GPS in underground environments have slowed the adoption of BIM, advancements in data capture and georeferencing technology are bridging this gap.

As these technologies evolve, the vision of a fully autonomous spraying system could become reality, with data-driven processes enhancing every stage of the project lifecycle from planning to completion.

“The core of Normet Performance Solutions is combining our technologies and data insights with our process expertise around tunnelling and mining. We’re constantly developing new ways to capture data and extract value from it,” says Oikkonen.

“Our goal is to turn this data into actionable insights that improve efficiency, safety, and environmental performance. It’s about knowing how to use the technologies effectively to get the best possible results for the user and the project.”

Read more about Normet’s leading technology shaping the modern mine in the whitepaper below.