The Tolillar project is a proposed lithium brine extraction development situated in the province of Salta, Argentina.

Alpha Lithium, a Canadian mineral exploration company, holds ownership of the project through its subsidiary, Alpha Lithium (Argentina), which is incorporated in Salta.

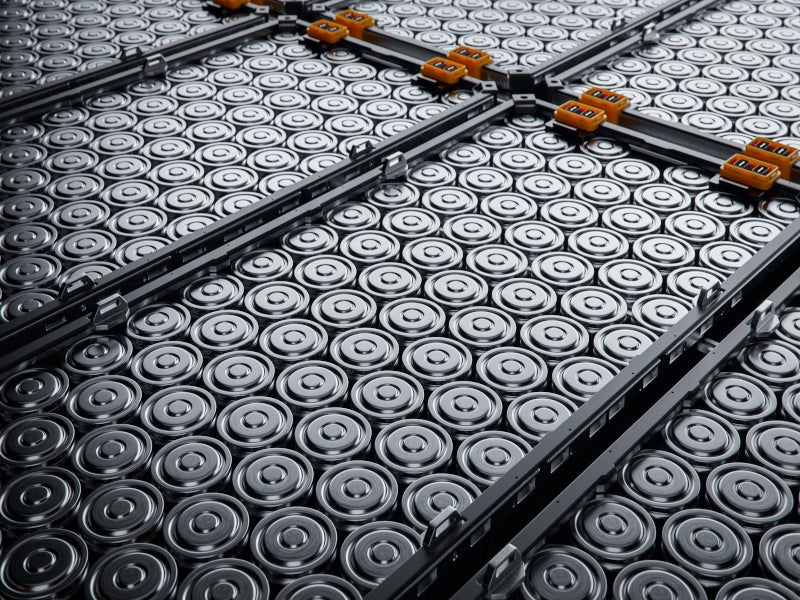

The mine’s maximum operational lifespan is projected to be 35.1 years, with an investment of $776.6m for the first phase of operations. The first phase is expected to have a production capacity of 25,000 tonnes per annum (tpa) of battery-grade lithium carbonate. The second phase will involve expanding production by an additional 25,000tpa.

The project’s updated preliminary economic assessment was announced in August 2023.

The construction is scheduled to begin in 2025. The production is estimated to commence in 2027, ramping up to full production by 2029.

Tolillar project location

The project lies within the Salar de Tolillar basin in the northwest region of Argentina’s Salta Province. It is about 170km from the city of Salta and 90km south of Estacion Salar de Pocitos.

Geology and mineralisation

The Salar de Tolillar project is embedded in the La Puna geological province, specifically within the Southern Puna geological sub-province. The region is known for its evaporitic basins, which harbour significant reserves of borates, sodium sulphate and lithium salts. The Salar de Tolillar is situated in one of these closed drainage basins.

The project’s mineralisation comprises lithium-enriched brine, contained within the pore spaces of the sedimentary strata in the Salar basin’s upper sections, and includes evaporite, alluvial and colluvial sediments.

Resources

The indicated resource for the Tolillar project is estimated at 3.62Mt of lithium carbonate equivalent (LCE), with an average lithium grade of 232mg/L.

The inferred lithium resources are estimated to be 1.39Mt of LCE, at an average grade of 180mg/L, as of August 2023.

Tolillar project mining method

The lithium production will involve the extraction of brine using a conventional brine production wellfield. Brine from individual production wells will be directed to two central collection/transfer ponds in the central part of Salar, from which it will be pumped through a main pipeline directly to the processing plant in the concession’s northernmost part.

The flow rates for each brine extraction well are expected to range from four to 25L/sec.

Around 40 wells are anticipated to be established within the first six years, with a total of approximately 108 wells projected by the project’s end. The production wells are expected to reach depths of down to 393m, targeting the sand and gravel layers for brine extraction.

Ore processing

Brine from various wells will be collected and channelled to a central point, then transferred to two storage ponds at the chemical facility before proceeding to the process feed tank.

The process feed tank phase will be divided into two parts. The first will utilise resin adsorption technology for direct extraction, yielding a lithium-enriched solution. This solution will subsequently undergo high-pressure reverse osmosis in the second part, concentrating the lithium levels to approximately 6,000mg/L – 7,000mg/L.

Divalent elements such as calcium and magnesium will be eliminated using sodium hydroxide and sodium carbonate, resulting in insoluble byproducts that will be subsequently removed. The purified brine will then advance to the carbonation stage.

During this phase, lithium carbonate will be produced through a chemical reaction with sodium carbonate. The ensuing mixture will be separated into a crude product and a concentrated solution. The lithium will then be refined by reacting with carbon dioxide to form highly soluble lithium bicarbonate, which will separate from the insoluble substances.

These will be filtered out, and the lithium bicarbonate-rich brine will be heated to release carbon dioxide, precipitating purer lithium carbonate. The high-purity lithium carbonate product will be dried, micronised and packed.

Tolillar site infrastructure

The project can be accessed from National Route 51, Provincial Route 27 and Provincial Route 17, complemented by internal roads. The nearest seaport is Antofagasta in Chile, 628km away overland.

The primary power source for the project will be a gas-fired electricity generation plant, which will supply approximately 34MW of power, satisfying the total electrical and heat power requirements of 13MW and 21MW, respectively.

Potable water will be transported to the site and distributed through public potable water stations, while process water will be sourced from groundwater extraction wells.

A camp will be designed to accommodate 350 workers and will feature six two-story buildings.

Contractors involved

Groundwater Insight, a Canadian consulting company specialising in hydrogeological studies and analysis, was responsible for the geological setting, deposit type, exploration work, drilling, sample preparation and analysis, data verification, and the development of the mineral resource estimate for the project.

Hydrominex Geoscience, a mining and metals consultancy company, completed the mine plan-related work.