The Cape Flattery silica sand project is an open-cut silica sand mining operation currently under development in Queensland, Australia. Metallica Minerals, an Australia-based company specialising in silica sand mining, is developing the project.

A pre-feasibility study (PFS) for the project was completed in March 2022, followed by a definitive feasibility study (DFS) in July 2023. Subsequently, an updated DFS was finalised in November 2023.

The project is projected to necessitate an initial investment of approximately A$236.7m ($152.05m) for a mine life spanning 15 years. It is expected to yield three million tonnes (mt) of marketable silica sand.

Cape Flattery project location

The project site is situated in the Cape Flattery region, on the eastern coast of the Cape York Peninsula in Queensland, approximately 45km from Hope Vale and 55km from Cooktown.

Geology and mineralisation at Cape Flattery

The Cape Flattery silica sand project encompasses a vast surface deposit of sand dunes atop the northernmost section of the Quaternary-aged Cape Flattery/Cape Bedford dune field complex. The geology consists of variably reworked aeolian sand (silica) dune deposits linked to the Quaternary-aged sand-dune complex.

High-grade quartz (silica) mineralisation is present as sand deposits within this aeolian dune complex.

Cape Flattery silica sand project reserves

The probable mineral reserve at the Cape Flattery silica sand project is estimated to be 47mt grading 99.11% silicon dioxide (SiO₂), as of November 2023.

Mining method at Cape Flattery

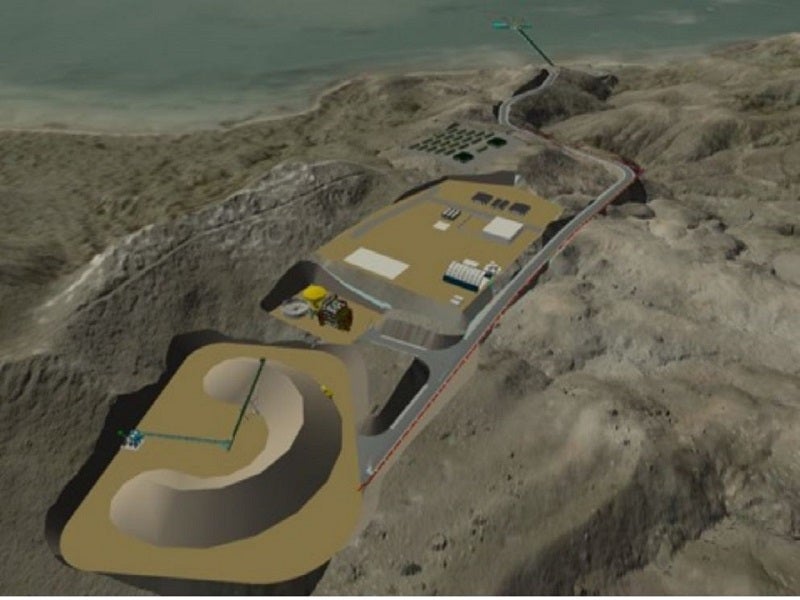

The project will be developed using open-cut mining methods with a rubber-tyred front-end loader (FEL) and slurry pumping extraction.

The mining operation will begin in the area where the ore reserves are nearest to the mine infrastructure. Sand extraction will be carried out on two fronts using two sets of dry mining units, each equipped with two loaders. The mining face will advance southwards and westwards throughout the mine’s lifespan.

Following vegetation clearance, topsoil will be stripped from a limited initial area using either a bulldozer or a grader. The plan is to stockpile the topsoil in 2m-high piles at the clearing’s edge for future rehabilitation purposes.

The extraction of silica sand will be conducted as a free-dig operation from the working faces using wheeled loaders. Areas containing silica sand of inferior quality will not be processed and will instead be allocated to rehabilitation sites. The anticipated average width of the mining face is 250m.

A FEL will undertake sand extraction and feed the material directly to the processing plant via a dry mining unit (DMU). The support mining fleet will comprise a bulldozer and an excavator.

During transit to the mobile feeder hoppers or DMU, water will be added to the silica sand, forming a slurry that will be conveyed to the processing plants through two separate slurry pipelines.

Processing at Cape Flattery silica sand project

Two wet concentration plants (WCPs) will be installed to process the run-of-mine (ROM) product. Each mining face will feed one of the two WCPs, operating independently.

The WCPs will be located to the northeast of the sand extraction area and are designed to reduce heavy mineral contaminants, which are predominantly oxides of iron, titanium, and aluminium.

Reject material from the WCPs, comprising low-grade silica sand with iron, titanium, and aluminium oxides, along with other minerals, will be returned to the active rehabilitation areas via pipelines, aiding in the progressive restoration of the extraction site.

Each WCP will possess a processing capacity of 1.5 million tonnes per annum (mtpa) and will be outfitted with a Lyons feed control unit surge bin, spiral separation, attrition scrubber, up-current classifier, low-intensity and wet high-intensity magnetic separators (WHIMS). The final product will undergo thickening and dewatering before being stockpiled for shipment.

The reclaimed product from the two stockpiles will be loaded onto a transhipment vessel via a single overland conveyor capable of handling 1,200 tonnes per hour (tph). The conveyor will span 1.2km, linking the product stockpile to the loading jetty.

Site infrastructure at Cape Flattery

A 350m-long piled jetty will be constructed to accommodate the overland conveyor. The barge loading facility will incorporate a tele-stacker mounted on rails, positioned on a crescent-shaped headstock supported by piles, capable of filling a 3,600dwt barge.

The project’s power requirements are proposed to be met initially by a low-voltage diesel power generation facility, with plans to supplement this with battery storage and solar power from the second year of operations.

Raw water is expected to be sourced from a borefield situated approximately 3.2km from the mine infrastructure area. The water will be pumped to a potable water treatment plant via a pipeline.

A 48-bed accommodation village, complete with dining and ancillary facilities, will also be established.

Offtake agreements

A memorandum of understanding (MOU) effective for 12 months, was signed in August 2022 with Mitsui for a possible offtake of all or specific portions of the silica sand products from the project. An agreement extending the MOU to September 2024, was signed in June 2023.

Additionally, Metallica Minerals signed a non-binding MOU with Eternal Asia Supply Chain Management in December 2023, valid for 12 months.