ArcelorMittal has patented a method for casting steel semi-products that involves monitoring light intensity from the liquid steel’s surface in a tundish. This method detects the presence of an open-eye and alerts operators when such a condition is identified, enhancing operational safety and efficiency. GlobalData’s report on ArcelorMittal gives a 360-degree view of the company including its patenting strategy. Buy the report here.

Discover B2B Marketing That Performs

Combine business intelligence and editorial excellence to reach engaged professionals across 36 leading media platforms.

According to GlobalData’s company profile on ArcelorMittal, Photovoltaic roof tiles was a key innovation area identified from patents. ArcelorMittal's grant share as of June 2024 was 62%. Grant share is based on the ratio of number of grants to total number of patents.

Method for detecting open-eye in steel casting process

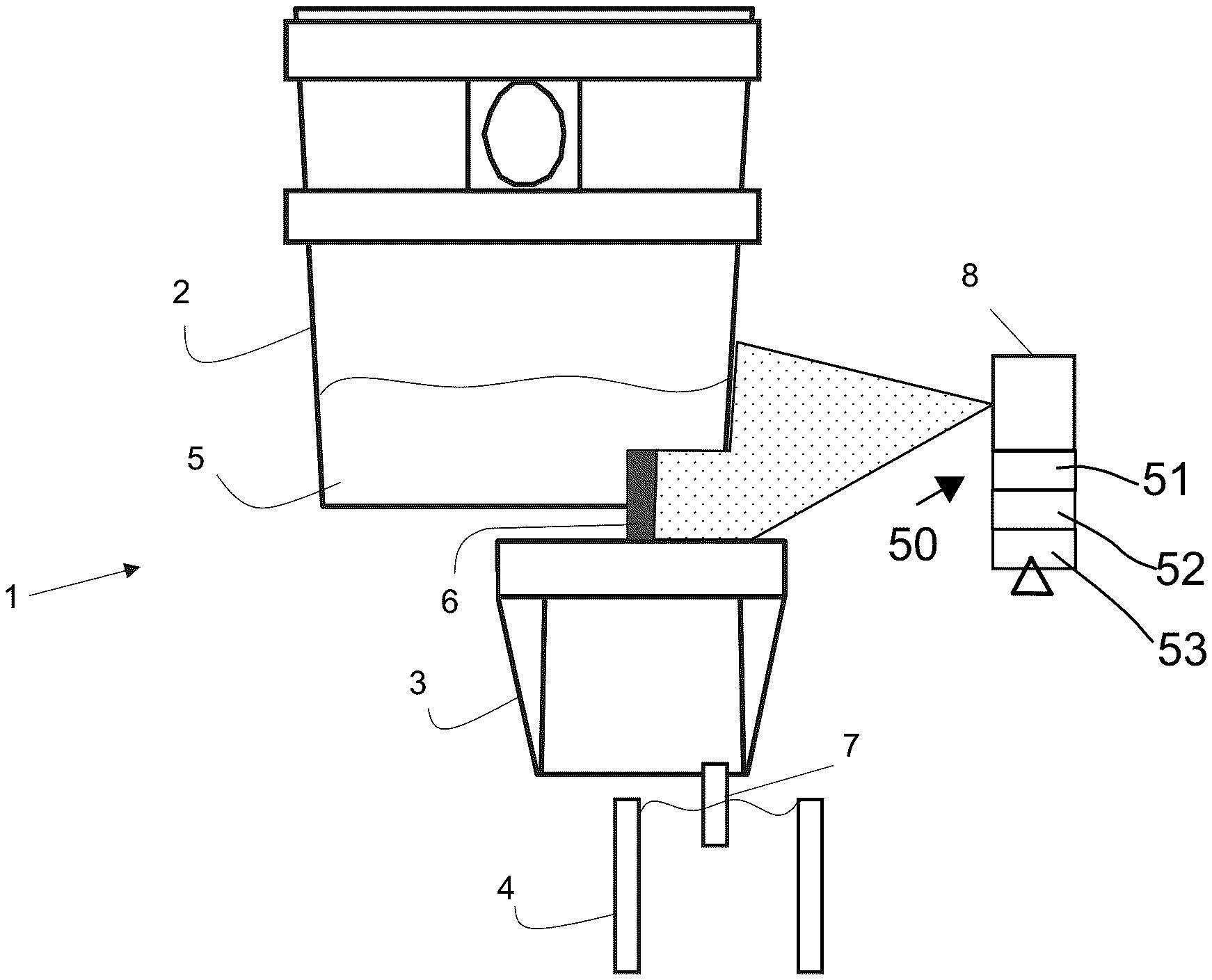

The patent US12042851B2 outlines a method for casting steel semi-products that enhances operational safety and efficiency by detecting surface anomalies in liquid steel. The process begins with pouring liquid steel from a ladle into a tundish through a shroud. A key feature of the method involves measuring the light intensity emitted from the surface of the liquid steel within the tundish. This intensity measurement is crucial for identifying the presence of an "open-eye," a defect characterized by a visible opening at the surface. Upon detection of such an anomaly, the system emits an alert to the operator, ensuring timely intervention. The method also includes calculating the size of the open-eye based on the light intensity, with alerts being issued only if the size exceeds a predetermined threshold.

In addition to the method, the patent describes casting equipment designed to implement this detection process. This equipment comprises a ladle, a tundish, and a mold, along with a measurer that captures light intensity data from the liquid steel's surface. The system is equipped with a processor that includes a determinator for assessing light intensity, a detector for identifying open-eyes, and an alert emitter for notifying operators. Notably, the measurer can be a light transmitter, enhancing the precision of the detection process. Overall, this innovation aims to improve the quality control in steel casting operations by providing real-time monitoring and alerts regarding surface conditions in the molten steel.

To know more about GlobalData’s detailed insights on ArcelorMittal, buy the report here.

Data Insights

From

The gold standard of business intelligence.

Blending expert knowledge with cutting-edge technology, GlobalData’s unrivalled proprietary data will enable you to decode what’s happening in your market. You can make better informed decisions and gain a future-proof advantage over your competitors.