The New Acland mine is an open-cut, thermal coal mine located near the Acland town, 14km north-west of Oakey Town, Queensland, Australia.

Owned and operated by New Acland Coal (NAC), a subsidiary of Australian mining company New Hope Group, the mine has been in production since 2002.

As the mine reserve was forecast to be depleted by 2017, NAC proposed the New Acland Coal Mine Stage-3 project expansion to extend operation and increase production capacity.

The plan was revised in 2012 and the same received approval from the federal government’s Environment Protection and Biodiversity Conservation Act (EPBC) in January 2017. The initial capital investment of the project is estimated to be approximately $500m.

The project is expected to extend the mine’s operation by approximately 12 years, while also increasing the mine’s thermal coal production capacity to 7.5 million tonnes a year (Mtpa) from the current production levels of 4.8Mtpa.

The mine is estimated to produce 80.4 million tonnes (Mt) of coal over the life of the mine, if the project proceeds.

New Acland Coal Mine Stage-3 details

The plan to expand the New Acland mine operations was first proposed in 2007. NAC, however, revised the project in 2012 to address the concerns raised by the Queensland government and local community about the potential impact of the project.

The revised project envisages the progressive development of two new resource areas within the new mining lease area, including Manning Vale and Willeroo, and three new pits, namely Manning Vale West, Manning Vale East and Willeroo.

The revised project has a considerably reduced disturbance footprint (approximately 63% less) and ensures that the mining operations will be located at least 10km away from Oakey Town.

Other changes include a relocation of the train loading facility from Jondaryan to a remote site closer to the mine and as previously proposed, the train loading arrangement will include a veneering system that seals the exposed coal at the top of each loaded wagon to reduce the potential for dust emissions during transport. This is a practice New Hope initiated and has been doing since 2013.

The estimated capital cost of the revised project is approximately $896m, with operating costs of approximately $450m a year. The estimated expenditure is approximately $6.6bn over the life of the revised project.

New Acland coal mine geology and mineralisation

The two resource areas to be developed as part of the revised project are located within the mineral development licence (MDL) 244, which is located in the north-west of the Moreton Basin over the northerly trending Kumbarilla Ridge, which separates the Moreton and Surat Basins.

While the Surat basin comprises early-Jurassic to early-Cretaceous age non-marine and marine sediments, the Moreton basin is made up of non-marine sediments dating from the late-Triassic.

The Walloon coal measures present in both the basins hold the economic coal-bearing sediments. The main coal bearing unit in MLD 244 is referred to by NAC as the Acland-Sabine Sequence.

Reserves

The revised Project’s JORC-classified reserves within four mining licenses, including MDL 244, for run-of-mine (RoM) tonnes total 441Mt.

Mining and processing at expanded New Acland coal mine

The truck and excavator/loader method, which has been in use at the open-pit mine since the beginning of its operations, will continue to be used.

The existing coal handling and preparation plant (CHPP) will be upgraded to account for the additional RoM coal throughput and a new CHPP Module 3, with a processing capacity of 750t/h of RoM coal, will be constructed.

CHPP Module 3 will be housed in a building, which will have a similar layout as that of the existing CHPP Modules 1 and 2, but will be widened to accommodate a second deslime screen. CHPP Module 3 will also have a larger dense medium cyclone (DMC) reject screen compared to the other modules. An overhead crane will provide access to the DMC.

A new sorting technology will be used in the wash plant for the coal processing. The processing of the raw-coal will be performed by using high-pressure air jets and X-ray to expel the rejected material before they are sent to wash plant.

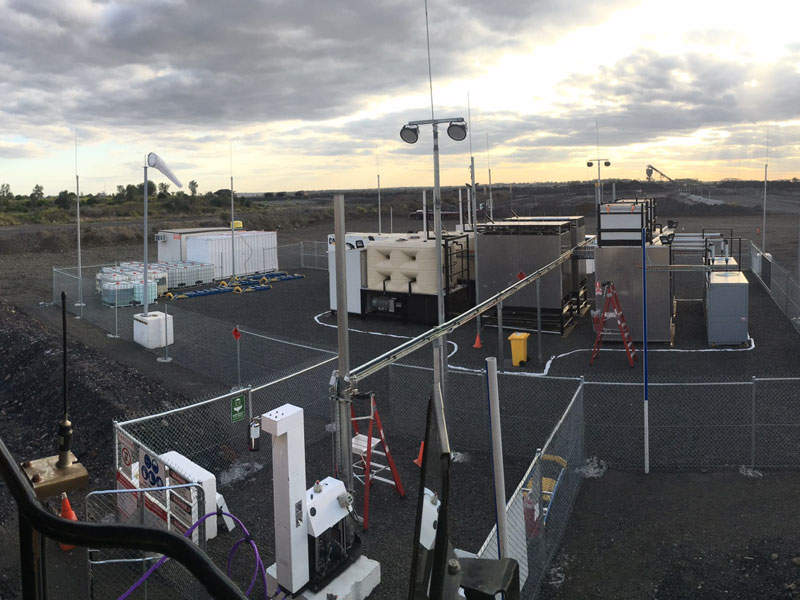

Major infrastructure developments for the expansion project

NAC revised the access and now propose to construct the Northern Mine Industrial Area Access Road at a new intersection location on Pechey-Maclagan Road west of Cherrys Road. This new road will enter into the new Mine Industrial Area (MIA) and will be designed to the appropriate standards to transport light vehicles into the revised Project site. The existing Jondaryan-Muldu road will be used as an internal haul road.

The existing 33kV mine and district 11kV power lines will be relocated and rebuilt. The current power requirement of the mine is 5MW/5.7MVA a year, which is expected to increase to 12.6MVA a year based on 7.5Mtpa full production.

Water for the Project will be sourced from predominantly onsite storages. NAC will purchase up to 5,500ML of Class A+ recycled water a year from Wetalla Wastewater Reclamation facility (WWRF), through a long-term contract to the year 2055. Additionally, NAC may also receive 150ML of recycled water a year from the Oakey Reverse Osmosis Treatment Plant (ROTP).

Treated in at on-site RO treatment plant, potable water is sourced from groundwater bores present on the site.

The Jondaryan rail load-out facility (JRLF) will also be relocated from the current location, to a new location in the mining lease area. A new 8km rail spur line and balloon loop, a new train load out facility, and a material handling facility will be constructed.

Benefits of New Acland mine expansion

The expansion will create up to 260 construction jobs and increase the number of operational jobs to approximately 410. NAC will encourage the use of local suppliers and contractors during construction and operations.