The Brakfontein coal project is an open-pit mine located in the Delmas district, east of Johannesburg in Mpumalanga, South Africa.

Universal Coal Development III, a joint venture between Universal Coal and Energy Holding South Africa (50.29%) and Unity Rocks Mining (49.7%), holds the right to mine and operate the project.

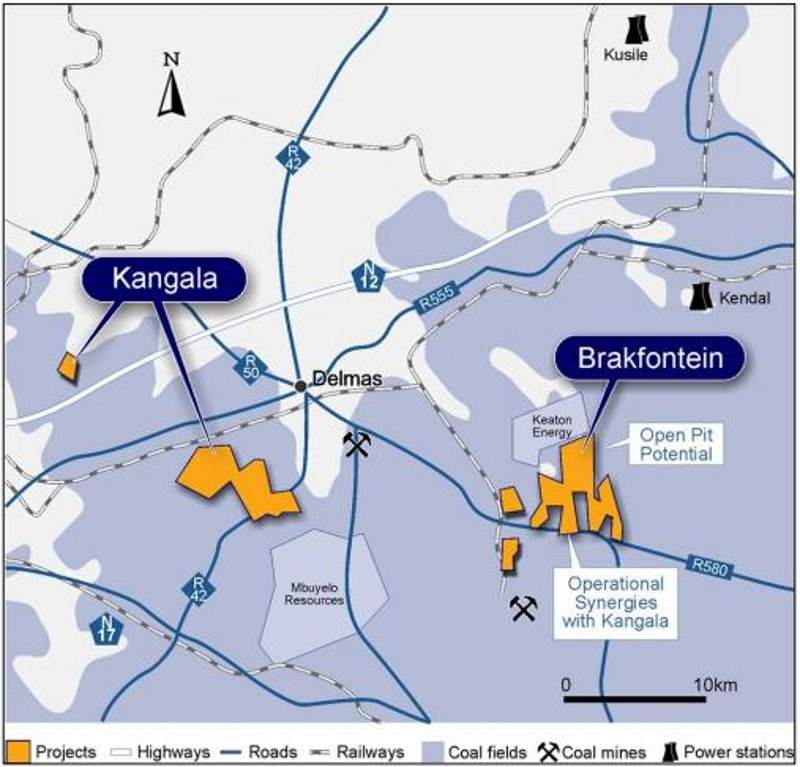

Brakfontein is Universal Coal’s third project in South Africa and is located 20km away from its Kangala mine, which produces more than 50% of the country’s export and domestic coal.

The pre-feasibility study (PFS) for the project was completed in 2014 and is currently being updated. The project received a water use license in September 2016. The Mining Right and Environmental Authorisation has already been approved and the project is set for the beginning of development.

The project is estimated to have a mine life of eight years and will produce 1.2 million tonnes (Mt) of coal per year during phase one of the development.

Production at the mine is expected to begin in late 2016.

Geology and mineralisation

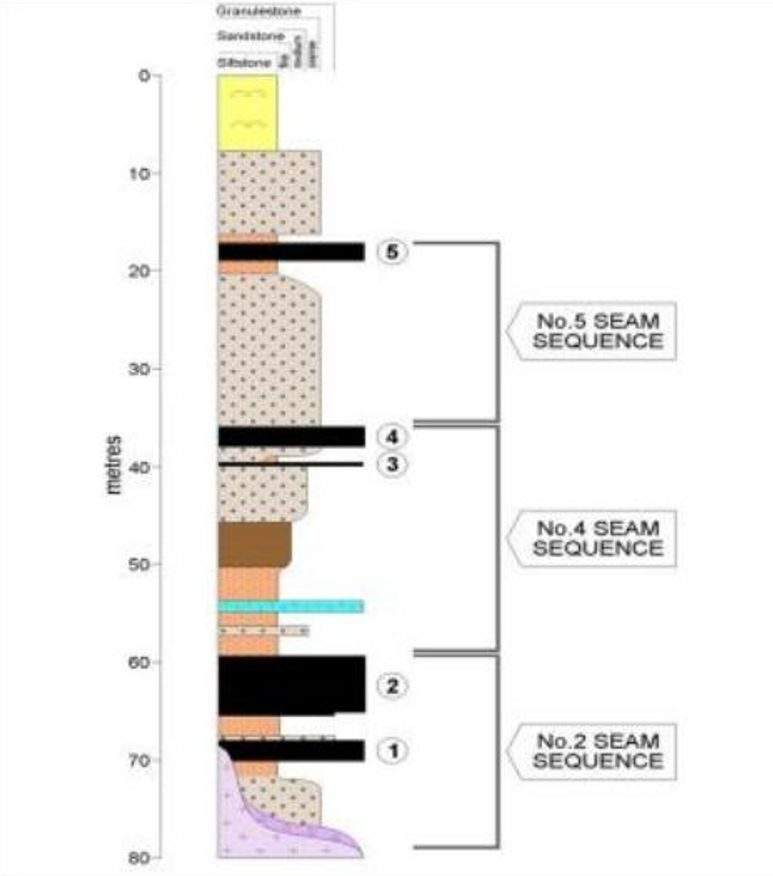

The Brakfontein mine is located in the Karoo Basin, which was formed between the late Carboniferous and Middle Jurassic periods with layers of Dwyka, Ecca and Beaufort groups and consecutive layers of the Molteno, Elliot, Clarens and Drakensburg formation.

The mine area comprises 40m-100m thick successive layers of sandstone, shale and coal. The coal-bearing Ecca group has been sub-divided into three different formations including Pietermaritzburg, Vryheid and Volksrust.

Coal reserves at Brakfontein mine

The mine is estimated to hold mineral resource of 75.8Mt, including 9.1Mt of proven ore reserve. It has a total of 31.7Mt of measured resources, 39.4Mt of indicated resources, and 4.7Mt of inferred resources.

The thermal coal produced from the mine will be sold to South African domestic power utility, Eskom.

Mining and processing at the thermal coal mine

The open-pit project will be mined using conventional truck and shovel methods, along with some bulk dozer push methods. Load and haul surface strip mining will be adopted for the northern open cast block of the mine.

The mined ore will be loaded and transported by conventional truck and backhoe excavator fleet, which includes four 100t excavators, 16 40t dump trucks, and two D10 dozers.

Before treating the raw coal at the processing plant, contaminants such as shale or stone will be added for dilution.

A processing plant, with a capacity to treat 100,000t of run-of-mine (ROM) coal a month, will crush and screen the diluted coal. Existing processing infrastructure available at the Kangala mine may also be used for the development of the mine.

Infrastructure at Brakfontein mine

Infrastructure required for operations at the mine will include box cut roads for transport, water management system with pumps, pipelines, storm water drains, pollution control dam, weighbridges, fencing, fuel depot, lighting, offices and maintenance workshops, coal stockpiles and waste yards.

Resources such as water, power and road infrastructure are available close to the project location. The facilities will be further developed to improve operations.

Contractors involved

The environmental impact assessment (EIA) study conducted during the pre-feasibility study was done by Digby Wells and Associates.