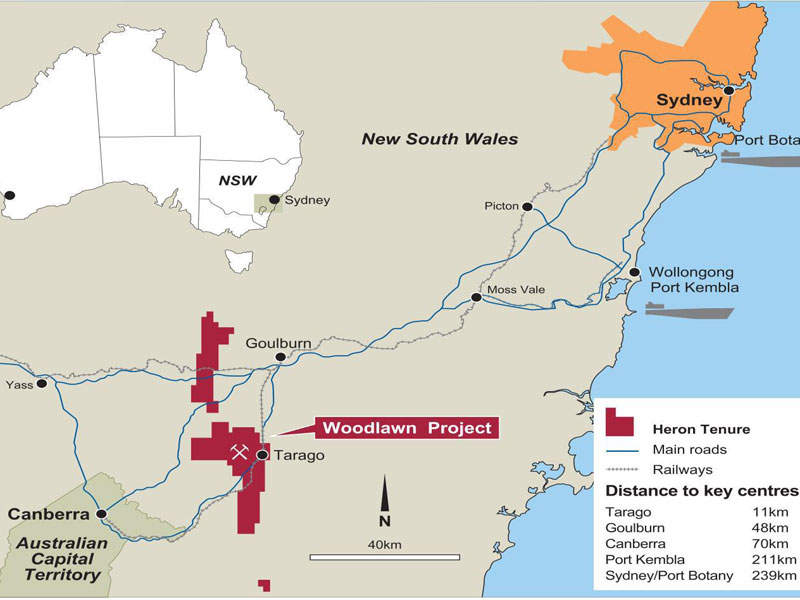

Heron Resources’ flagship Woodlawn Zinc-Copper project is located within the mining lease SML 20, approximately 11km from Tarago, 48km south of Goulburn, 70km north-east of Canberra, and 239km south-west of Sydney, New South Wales (NSW), Australia.

The project proposes an integrated development of the Woodlawn Underground Project (WUP) and the Woodlawn Tailings Retreatment Project (WRP), with processing of the separate underground and tailings ore types deploying a single sulphide flotation plant, to produce copper, lead and zinc concentrates.

The preliminary economic assessment (PEA) study for the project was completed in June 2015 and the feasibility study was completed in June 2016. Production from the project is anticipated to start in late 2018.

The zinc-copper project is estimated to require an A$240m ($183.53m) investment. Heron secured the full funding package for the construction and optimisation of the mine in June 2017. The initial mine life is estimated at 9.3 years.

Project history and ownership

The Woodlawn Zinc-Copper deposit was discovered in 1969 and was developed by Denehurst from 1978 to 1998. The open-pit mine was further acquired by TriAusMin, who merged with Heron Resources in August 2014.

Woodlawn Zinc-Copper project geology

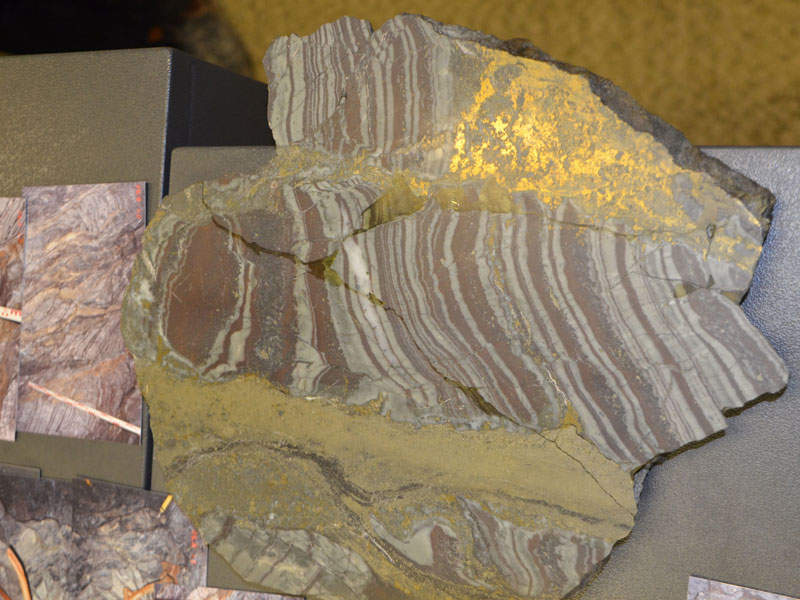

Woodlawn is located in the Goulburn Basin within the Lachlan Ford Belt. The deposit is hosted primarily by regionally metamorphosed fine to coarse grained, felsic to intermediate volcanic rocks and volcanogenic sedimentary rocks, including carbonaceous shale, known as the Woodlawn Volcanics to a lesser extent.

The mineralisation is classified as a volcanogenic massive sulphide (VMS) mineralisation consisting of strata-bound lenses of pyrite, sphalerite, galena and chalcopyrite. Three specific mineralised horizons at the deposit host 12 sulphide lenses within a 400m x 600m, and a north-west plunging envelop more than 900m-long.

Reserves at Heron Resources’ flagship project

WUP is estimated to hold combined proven and probable mineral reserves of 2.8Mt grading 14% zinc equivalent (ZnEq), 5.5% zinc (Zn), 1.6% copper (Cu), 1.9% lead (Pb), 0.45 grams per tonne gold (Au/gt), and 42 grams per tonne silver (Ag/gt).

WRP is estimated to hold combined proven and probable mineral reserves of 9.5Mt grading 6.0% ZnEq, 2.2% Zn, 0.5% Cu, 1.3% Pb, 0.31Au/gt, and 31Ag/gt.

Mining and processing at the NSW zinc-copper project

The underground mining methods selected for the WUP include drift and fill (DAF), underhand longitudinal open stoping, and underhand transverse open stoping.

The method selected for mining the existing tailings dam south (TDS), tailings dam west (TDW) and tailings dam north (TDN), as part of the WRP, is the automated monitor-based hydraulic mining, deploying high-pressure water cannon to stir the ore into a slurry.

The processing plant is designed to process 1Mtpa of underground ore and 1.5Mtpa of reclaimed tailings. It incorporates an IsaMill grinding machine for the WRP and two-staged crushing circuit and a primary grind ball mill for the WUP.

The remaining plant circuits have been designed to enable a quick change from one configuration to the other in the processing of the two different ore types. The processing plant will incorporate conventional and fine grinding circuits and separate flotation circuits for the extraction of copper, lead and zinc concentrates.

The concentrates will be thickened and filtered on-site and transported by trucks to either Port Kembla or Port Botany, for further export to smelters.

Infrastructure for the Australian zinc-copper mine

The project benefits from existing infrastructure, which includes a sealed access road, administrative buildings and offices, Essential Energy-owned 66/11kV electrical substation and 66kV transmission line, a raw water tank, evaporation ponds, and associated water pipes and ponds.

The raw water required for the project will be sourced from the Willeroo Borefield and stored in the existing 10,000m³ raw water dam at the project site, whereas the process water will be sourced from a new 10,000m³ process water dam, fed by the tailings thickener overflow.

Other infrastructure at the site will include tailings management facilities, waste dumps, a reverse osmosis water treatment plant, communications facilities, sewerage facilities, air circuits for the WUP, communications systems, and additional buildings.

Key players involved

The feasibility study was conducted by SRK Consulting with inputs from GR Engineering Services (GRES) for the recovery methods, process plant, infrastructure, tailings storage, and related capital and operating costs.

Beck Engineering was contracted for the geotechnical work, Outotec for the paste-fill testwork, and Australian Mineral Metallurgical Laboratories for the metallurgical testwork.

Sedgman was awarded a $81.82m engineering, procurement and construction (EPC) contract for the project in May 2017. Ertech was contracted to perform earthworks at the mine in, May 2017.