The Soledad Mountain gold-silver project is a fully permitted, open-pit, heap-leach gold and silver project being developed in Mojave, Kern County, California, US. The project is a 50-50 joint venture operation of Golden Queen Mining (GQM), and Gauss, which was owned by Leucadia National Corporation and Auvergne.

The Kern County Planning Commission approved the project in April 2010. Construction of the mine started in July 2013 and the final construction engineering designs were completed in 2014. The project is expected to start production in late 2015.

The gold-silver mine is expected to produce an annual average of 74,000oz of gold and 781,000oz of silver over its mine life of 12 years.

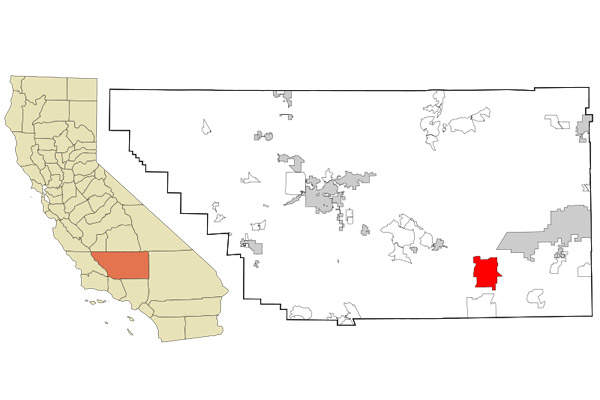

Soledad Mountain project location, geology and mineralisation

The Soledad Mountain gold-silver project is located in Kern County in southern California, approximately five miles south of the town of Mojave. The deposit comprises rock types of extrusive volcanic origin, quite similar in chemical composition and high in silica with little or no clay.

The project is located within the Mojave structural block, a triangular-shaped area bordered by the north-west-trending San Andreas Fault in the east and by the north-east-trending Garlock Fault in the north.

Northwest-trending, en-echelon faults and fracture systems host most of the gold-silver mineralisation at Soledad.

Reserves at the Soledad Mountain deposit

As of 1 February 2015, the Soledad Mountain project is expected to contain proven and probable ore reserves of 46.3 million tonnes (Mt) grading 0.661g/t of Au and 11.09g/t of Ag. Contained reserves are estimated to be 983,600oz of gold and 16.51 million ounces (Moz) of silver.

Mining and processing of ore at the Soledad Mountain project

Conventional open-pit mining method, including loading and hauling, will be applied at the project. The run-of-mine ore will be delivered to the crushing-screening plant located south of the phase one heap leach pad.

The crushing-screening plant will consist of a four-stage crush with a high-pressure grinder roller (HPGR) for the tertiary stage. Ore will be fed directly to the primary crusher or stockpiled adjacent to the primary crusher.

The crushed ore will be conveyed to a coarse ore stockpile and then delivered to the secondary crusher and the HPGR comprising two counter-rotating rolls, a fixed roll and a ‘floating’ roll.

The HPGR discharge will be conveyed to an agglomeration drum where cement and process solution will be added, and then conveyed by overland and a series of grass-hopper conveyors to a stacker and placed on the heap leach pad.

Gold and silver will be recovered by dissolution in a dilute sodium cyanide solution and then by precipitation with zinc or adsorption on activated carbon (termed as the Merrill-Crowe process).

After precipitation, the solution will be pumped to plate and frame filter presses to remove the gold and silver precipitates. The recovered precipitate will be dried and mixed with selected fluxes, typically silica, borax and soda ash, and sodium nitrate, and melted in an induction furnace to produce a slag.

Romarco is developing the Haile open-pit gold mine in Lancaster County, South Carolina, US.

The slag will be cooled and crushed, and the occluded particles of gold and silver will be recovered by gravity for further processing. The molten mix of gold and silver (doré) will be poured into a series of cascading moulds.

The doré will be cooled, cleaned and shipped to Johnson Matthey’s refinery in Salt Lake City, Utah. It will be smelted and refined to produce saleable gold and silver, which will be sold by Johnson Matthey at spot price on the day it is produced.

Infrastructure facilities at Soledad Mountain

Southern California Edison (SCE) will supply the power required for the mining operations, through a 12.5kV line that runs along the property boundary.

Initial water supply for the mine will be provided from the production wells or the Antelope Valley-East Kern Water Agency (AVEK) supply point.

Key players involved

Kappes Cassiday & Associates (KCA), Mine Development Associates (MDA) and Norwest Corporation prepared the technical report for the gold-silver project.

KCA is also responsible for the design and construction of the Merrill-Crowe plant on a turnkey basis. Gary Little Construction was engaged for the construction of the Merrill-Crowe plant building, building foundations and building services.

Turn-Key Processing Solutions (TPS) and Management performed the detailed design of the crushing-screening plant for construction, while Golder Associates designed the phase one heap leach pad.

A-C Electric, and Project Management prepared the detailed electrical design, construction cost estimates and power consumption estimates for the project.