Ontario Graphite (OGL) is re-commissioning the Kearney open pit graphite mine located in Canada, one of the top ten gold producing countries in the world. The mine is known to contain the largest confirmed graphite resources in North America and will make Ontario Graphite one of the only two producers of natural flake graphite in North America when production begins.

The final operating permit for restarting the Kearney mine was received in May 2013. The graphite mine has an expected operational life of more than 50 years and will feature an open pit mine and milling facility. It is expected to begin production and become fully operational in 2014, producing an estimated 20,000t of natural flake high-carbon graphite concentrate annually by processing approximately one million tonnes per annmum (Mtpa) of ore. The finished product will be directly sold to the end-user.

The mine currently employs 20 full-time employees and is expected to create approximately 80 direct jobs.

Kearney mine history, geology, and reserves

Owned by Northern Graphite, located between the cities of Ottawa and North Bay in Ontario, Canada, approximately 15km from the Trans-Canada pipeline and highway.

The Kearney graphite mine, located in the Town of Kearney, Ontario, was operated by Cal Graphite Corporation from 1989 to 1994 before placing it under maintenance and care. Approximately 17,000t of graphite was produced from the mine during the five-year operational period. The Kearney mining concession was acquired by Ontario Graphite in 2006.

The mine is located within the Central Gneiss Belt (CGB), a part of the Grenville Province. The province extends from Lake Huron, to the west, through Quebec and Labrador, and into New York State to the east. The Grenville province is sub-divided into two lithologic zones the CGB, the Central Metasedimentary Belt (CMB), and two structural zones, the Grenville Tectonic Zone and the CMB Tectonic Zone.

Measured and indicated resources at the mine as of August 2013 are estimated to be 51.5 million tonnes (Mt) at an average grade of 2.14% carbon graphite (Cg). Inferred resources are estimated to be 46.8Mt of ore graded at 2.0% Cg.

Mining and processing of ore at the Kearney mine

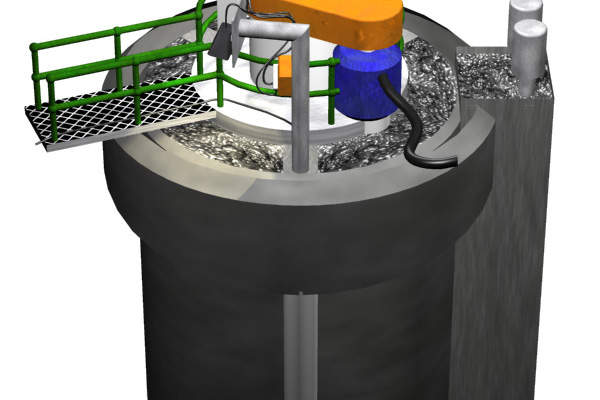

The graphite-rick rock ore will be extracted from the open pit mine and trucked to the processing mill. The ore will be crushed in a crushing circuit comprising a 48in x 60in jaw crusher and transported to the hydraulically driven semi-autogenous grinding mill via conveyors.

Outflow from the SAG mill will be screened by a wet screen, which will re-circulate the oversize back to the mill. Grinded and crushed material will pass through the floatation circuit where it will be cleaned and polished with the help of two rougher and cleaner columns.

Exhaust heat from the generators will be used to dry concentrate, while radiated heat will provide warmth during winter. Dried material will be packed in one tonne tote bags and trucked for delivery to customers.

The non-graphite bearing rock (waste rock) will be deposited at the waste rock area, just south of the open pit. The tailings generated during milling process will be shifted to the tailings storage facility.

Infrastructure facilities at the new Kearney graphite mine

The re-commissioned Kearney mine will make use of the already existing mine and mill infrastructure, saving approximately $60m for OGL.

Four 1.24MW diesel generators, of including three for operation and one for standby, will supply the power required for the mine, while water required for mining operations will be sourced from nearby lakes, ponds and wells.

Contractors involved with the Kearney graphite mine development

Golder Associates conducted the Mineral resources estimate for the Ontario graphite’s new mine at Kearney. Merit Consultants was awarded the construction management contract for the new graphite mine. The SAG mill will be supplied by Tenova TAKRAF.