The Kusasalethu mine, formerly known as Elandsrand, is a project being developed beneath the existing mine, adding a further 18 years of life to the operation and allowing 9.8Moz of reserves to be exploited. The deepening project is almost complete.

The mine was renamed in February 2010. Kusasalethu mine employed 5,756 employees and contractors and produced 180,334oz of gold in 2011. The production output will be 450,000oz of gold a year, with full production set to be achieved by 2013.

Located in Far West Rand, 1km south-west of Carletonville, Mpumalanga, Harmony acquired Elandsrand in February 2001, along with the adjacent Deelkraal mine – known collectively as Kusasalethu – from AngloGold for a cash price of R1bn.

Geology

The Witwatersrand is home to the world’s richest gold deposits and three identified main reef groupings – the Ventersdorp Contact Reef (VCR), the Carbon Leader Reef (CLR) and the Mondeor Reef – are contained in Elandskraal. Of these, only the VCR is economic and has been mined between 1,600–2,800m below surface; future production at the Elandsrand mine will be down to 3,600m.

Both the VCR and CLR are narrow, tabular ore bodies, 0.2–2m thick, consisting of quartz pebble conglomerates hosting gold, with extreme lateral continuity.

Mine project

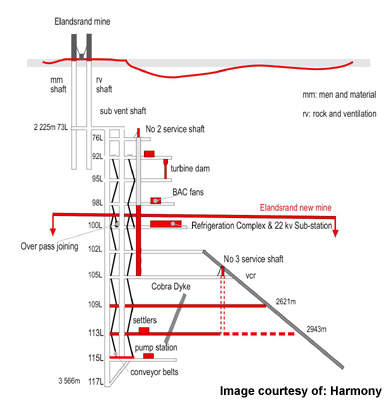

During the period when Elandsrand was managed by AngloGold, production came mainly from the workings between 73 and 98 levels, though over time these reserves were progressively mined out.

Based on a feasibility study undertaken in 1990, AngloGold decided to extend the life of the mine by exploiting the western high grade VCR block, below the limit of the then existing infrastructure, at depths from 3,000m to 3,500m below datum. The plan was to deepen both the sub-vertical and sub-ventilation shafts by around 500m apiece and then develop the reef on four new levels – 102, 105, 109 and 113 respectively.

After acquisition, Harmony have continued with the deepening project – now termed the ‘new mine’ – making a capital investment of over R600m to counter Elandsrand’s declining production profile.

Apart from deepening the sub-shafts and developing access for the mine, a variety of other aspects have had to be addressed, including raising the reef and waste ore pass system, installing new rock hoisting facilities and integrating the two mines’ ore pass systems.

In addition, the work calls for the sinking of two settling dams, together with the provision of underground pumping stations, a refrigeration chamber, two service shafts and a turbine chamber and dam.

Kusasalethu progress

Project delivery has not been without its setbacks – most notably in November 2002 when a high-pressure gas pocket was released with the blast on 109 level as a result of intersecting the Cobra Dyke. Although the dyke was intersected in the upper levels of the mine, it is not associated with much gas there. As a result, the work on 109 and 113 levels was put roughly two years behind schedule, with development on the upper levels to give access to the Deelkraal reserve being accelerated to offset the delay.

Overall, good progress has been made, with capital access development being completed on levels 105 and 109 by the first half of 2007 and cash operating cost development taking place in easterly and westerly directions on 102, 105 and 109 levels.

Arrangements for the clear water and mud handling are also well advanced. A series of annex holes have been drilled from level 102 down to level 113, where the water will enter two 10m-diameter high flow settlers installed on top of the clear water dams between 113 and 115 levels.

A new pump station on 115 level completed in March 2011 is equipped with four seven-stage 2.4MW pumps. It delivers clear water from here up to existing clear water dams on 98 level, with settled mud being pumped to the existing mud dams on 100 level.

Re-engineering the closed loop chilled water system has allowed the project to make significant reductions in high-pressure piping. Having service water fed to the workings on each level from the discharge side of the air coolers, enabling surplus ‘cool’ water to be returned to the 98/100 level dam, results in fewer chilled water columns being needed.

The cooling for the mine is supplied by two 3.5MW Bulk Air Coolers (BACs) located on 100 level, which receive a water feed from three 3.5MW refrigeration plants installed on the same level – air for the BACs was supplied by two Axial AFN Booster fans.

A 22kV sub-station equipped with two 10MVA transformers, completed in early 2011, feeds the refrigeration complex in operation. Developing the refrigeration chambers themselves proved challenging, since the work had to be done behind the existing mid-shaft loading arrangement on 100 level; all the production from the original mine – above 100 level – had to be subsequently hoisted.

Mine fatalities

During January 2009, production at the mine was halted for two days because of a fatal accident caused by a seismic event. The mishap occurred in the 95/10 W4 panel, around 2,780m below surface. Another mine fatality occurred in May 2011. The mining operations were temporarily suspended again in November 2011 due to another mine fatality.