During 1993, in a bid to replace declining copper reserves at its Mount Isa operations, MIM Holdings bought into a Queensland copper-gold property that had been explored by Savage Resources and others. After mineral rights issues were resolved, MIM formed Ernest Henry Mining Pty Ltd (EHM) in a 51/49% joint venture with Savage Resources to develop an A$350m open pit designed to mine 9–10Mt/y of ore.

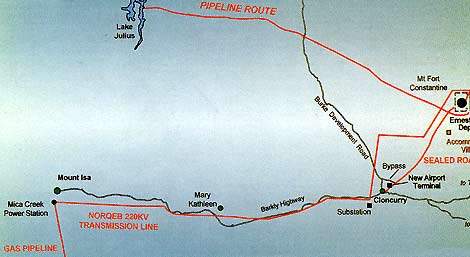

Named after the prospector “father” of Cloncurry, 38km to the southwest, Ernest Henry is 160km from Mount Isa. It officially opened, ahead of schedule and under budget, in October 1997 and commercial production at targeted rates started in May 1998.While about 3,500 people were involved in the mine’s construction, the workforce now comprises 233 employees and 165 contractors.

In 1999 the Australian base-metals firm, Pasminco, took over Savage Resources, and in 2001 opted to sell its EHM holding. MIM exerted its pre-emptive right to buy, using financing from Westpac, and immediately sold the interest to a company owned by Westpac and others, with an option to re-acquire the holding. EHM is now wholly owned by Xstrata plc, following that company’s takeover of MIM in mid-2003.

Geology and resources

The breccia orebody occurs within a folded Middle Proterozoic volcanic sequence and comprises altered and replaced felsic volcanic fragments in a matrix of magnetite, chalcopyrite and carbonate. It dips 30–50° SSE, is about 250m thick, averages 300m in width and is open at depth. The copper, gold and other mineralisation is thought to have originated from a nearby granite intrusion. Weathering and oxidation to as much as 150m has created supergene ore that comprises 12% of the resource, with native copper, bornite, chalcopyrite and gold. The primary ore in the deposit contains chalcopyrite with bound-in gold.

As of June 2005, proved reserves stood at 48Mt @ 1.0% Cu and 0.5g/t gold. Open-pit mineable mineral resources also totalled 48Mt at 1% copper and 0.5g/t gold.

Mining

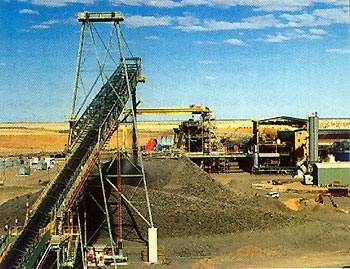

The open pit is to be mined in eight stages with a strip ratio of 5:1, extending to a 5km perimeter, 1.3km diameter and a final depth of 570m. Driltech rotary rigs drill 17m holes for blasts of up to 500,000t. A P&H 4100A shovel with a 43m³ bucket joined the original Liebherr 996 hydraulic excavator (with a 30m³ bucket) when the mining rate was increased. These machines mainly load 14 Komatsu 218t-capacity trucks. Contractors initially did the mining but MIM took over in 1999.

Groundwater extracted to keep the mine dry is used for dust suppression and processing, but the main water supply is from Lake Julius, 110km to the west.

Processing

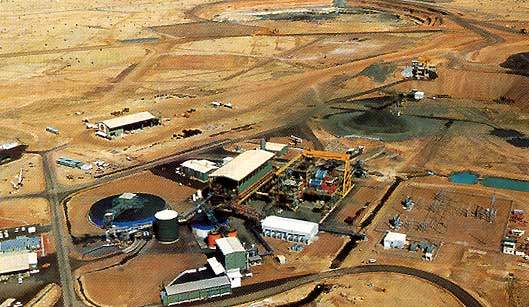

The single line 1,200t/h process-controlled plant is designed to produce 350,000t/y of concentrate containing 95,000t of copper and 120,000oz of gold. A gyratory and other crushers feed the 11MW SAG mill / 5.5MW ball mill circuit via a stockpile. A separate milling circuit extracts native copper while copper-gold minerals are separated by rougher and cleaner flotation with Vertimill regrinding. Roughing is in 127m³ Wemco Smartcells and three-stage cleaning in 50m³ and 16m³ Outokumpu OK cells. Dewatering involves one tailings and one concentrate Eimco thickener and a 144m² Larox concentrate pressure filter. EHM pumps tailings to an engineered storage facility.

About 1,000t/d of concentrate is trucked by a specially formed company, Queensland Bulk Haulage, to the Mount Isa copper smelter, which was expanded accordingly.

Production

MIM’s share of Ernest Henry ore treated rose from nearly 3.3Mt in the company’s 1998 Financial Year (FY) to a peak of 5.24Mt in FY2001. Although ore grades varied, copper-in-concentrate output rose from 26,000t to 53,800t over the same period, and contained gold from 33,750oz to 60,530oz. In calendar 2005, Ernest Henry mined 11.5Mt of ore and processed 11.4Mt. Concentrate production totalled 442,407t, containing 129,000t of copper and 167,224oz of gold, both substantial increases over the output achieved in 2004.