The Osborne copper-gold mine is located 195km south-east of Mount Isa in Queensland, Australia. Run as a fly-in, fly-out operation for its 180 staff, the mine was formerly wholly owned by Placer Dome Inc. In early 2006, Barrick Gold Corp acquired Placer Dome in a US$10.4bn takeover, and now wholly owns the Osborne operation. Production in 2005 was 39,475t of copper and 43,000oz of gold.

Production began in August 1995, open-pit mining finished in February 1996 and was replaced by output from the underground section in April 1996. An underground crushing and hoisting system was commissioned in mid-1998.

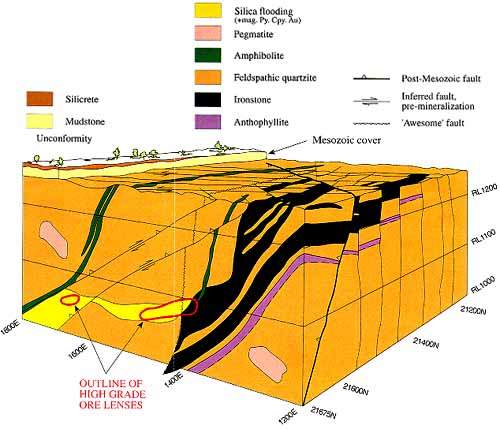

Geology and reserves

Osborne is based on an ironstone-hosted, replacement-type copper-gold deposit. It has a complex polyphase deformation history with evidence of early compression followed by multi-stage metamorphism.

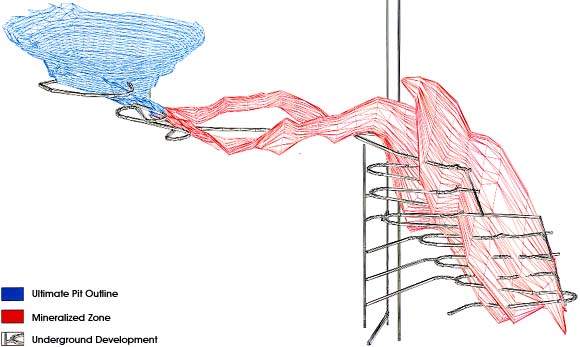

The main orebody (the 2N ore zone) lies immediately beneath a mesozoic formation. A second orebody (1S ore zone) runs parallel to the 2N zone but only reaches mineable widths at its southern end. Both of these zones extend below 600m from surface. A third zone (the 3E ore zone) to the east forms a high-grade pod about 200m below surface.

Chalcopyrite is the primary copper mineral, occurring as very coarse grains associated with replacement and brecciation textures which are common in the zones of massive silicification. The contained gold:silver ratio is in the order of 1:1.5 with native gold and silver being relatively rare.

As of the end of 2005, proven and probable ore reserves totalled 5.9Mt grading 2.2% copper and 0.8g/t gold, containing 132,500t of copper and 161,000oz of gold. In addition, there were 4.2Mt of indicated and inferred resources grading around 2% copper and 1g/t gold.

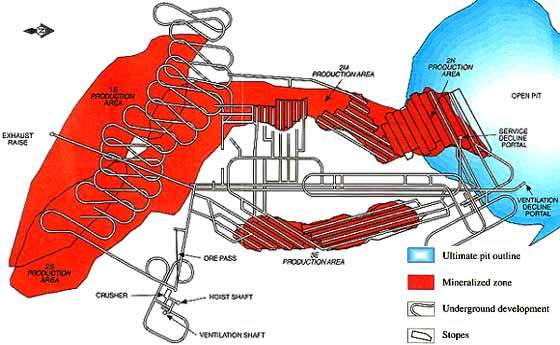

Mining

Access to the underground mine is via a decline with a portal located in the wall of the open pit, 80m below surface. Open-panel stoping accounts for recovery of around 90% of the in-situ ore, with 89mm-diameter blast holes, 20m long, being drilled to break the ore. Uphole bench stoping is used at depth. No fill is used to replace the mined ore. Development drilling is carried out using two Sandvik (Tamrock) electro-drilling jumbos, while broken ore handling employs four 6m³-capacity Caterpillar 2900 LHDs and three Caterpillar mine trucks.

The primary jaw crusher is located underground. The shaft hoisting system has a capacity of 2.3Mt/y and uses a large single skip running from the underground crusher station to surface.

Ore processing

Osborne’s concentrator uses both gravity separation and flotation to recover gold and copper concentrates respectively. The original flowsheet design included a carbon-in-pulp gold recovery circuit, intended to recover around 50% of the gold as doré from a pyrite flotation concentrate. However, this system was abandoned after it was discovered that 60–70% of the contained gold reports to the copper concentrate, and a new gravity circuit, designed around a Knelson concentrator, was installed in its place. As well as recovering free gold, this allowed the concentrator throughput to be increased from 1.0Mt/y to a nominal 1.2Mt/y, although this has been exceeded since. Mill throughput in 2001 was 1.49Mt, equivalent to 4,074t/d.

After further crushing in a small gyratory crusher and grinding in a rod mill and ball-mill circuit, free gold and copper concentrates are recovered by gravity and flotation. Pyrite is also recovered since this contains some of the gold. Saleable products are a copper-gold concentrate containing 28% copper and 5.0g/t gold, and gold doré. Recent recoveries have been 96% for copper and over 79% for gold.