Cortez is approximately 113km south west of Elko, Nevada. It consists of three distinct units: the Cortez open pit and two Carlin-type disseminated gold deposits – Pipeline and South Pipeline. Until February 2008 the operation was 60%-owned by Barrick Gold, having acquired Placer Dome for US $10.4bn in 2006, and 40% by Rio Tinto.

In February 2008 Rio Tinto reached an agreement on its stake in Cortez, selling it to its joint venture partner as part of its planned programme to divest at least $15bn of assets. The sale price included a cash consideration of $1.695bn. In addition, Rio Tinto will benefit from a deferred bonus payment in the event of a significant future discovery of additional reserves or resources at the mine and will also retain a contingent royalty interest in the future production of the property.

Geology and reserve

Production began at Cortez in 1969 with the Pipeline deposits, where mining is now centred, being discovered subsequently.

The Pipeline deposit is situated along the Cortez/Battle Mountain trend in the north-central Nevada basin-and-range province. Submicroscopic gold particles are evenly distributed throughout carbonate host rocks. The two principal lithological units are a sheared and altered thinly-bedded calcareous siltstone and quaternary alluvium varying from chert, argillite, siltstone, limestone and quartzite to fine sands and silts.

Proven and probable reserves in January 2005 totalled 234Mt grading 1.4g/t gold, equivalent to 7.8Moz of gold at 74% recovery. In September 2005, the joint venture approved the development of the nearby Cortez Hills deposit, discovered in 2003, where proven and probable reserves of 64.7Mt at a grade of 1.8g/t gold contain a further 5.5Moz.

Mining

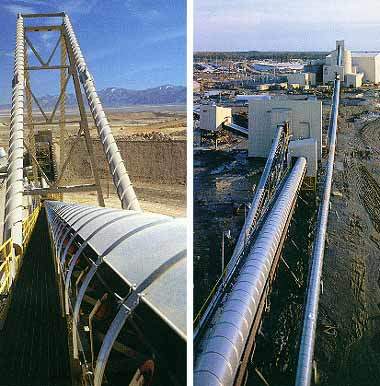

Conventional open-pit mining methods are used for the Pipeline and South Pipeline deposits, scheduled in nine stages. From 2001 to 2005, production averaged 70Mt/y. Mining is carried out with electric shovels, a hydraulic shovel and haul trucks. A fleet of miscellaneous equipment includes rotary/hammer blasthole drills, wheel loaders, bulldozers, graders and water trucks.

A pit dewatering system including 40 wells helps to prevent water inflows, the water being transported from the pit to a series of shallow infiltration ponds for recycling.

Ore processing

The original Cortez concentrator was placed on care-and-maintenance in late 1999, following the change from milling ore to heap-leaching ore from the Pipeline pit. Consisting of crushing, dry grinding, circulating fluid bed roasting, wet grinding and carbon-in-leach gold recovery facilities, it may be re-opened to treat suitable ore towards the end of the mine’s life.

The Pipeline concentrator has a throughput of 8,650t/d, having been designed to handle various types of oxide ore from the Pipeline and South Pipeline orebodies. Its flowsheet consists of primary crushing, autogenous/ball mill (AG) grinding, carbon-in-leach and carbon-in-column gold recovery systems, together with carbon stripping, reactivation and gold refining facilities. Low-grade, run-of-mine oxide ore is heap-leached, with gold-bearing carbon from this section being returned to the main concentrator for gold recovery.

Run-of-mine oxide ore is crushed and stockpiled before grinding in an autogenous mill and a ball mill. Discharge from the AG mill is screened, with screen oversize being conveyed to a cone crusher and recycled to the AG mill. Screen undersize and ball mill discharge are sized in hydrocyclones, the overflow being thickened to provide feed for the carbon-in-column (CIC) and carbon-in-leach (CIL) circuits.

The CIL circuit consists of eight CIL tanks, 16 screens and eight carbon-forwarding pumps. Retention time at the 9300t/d throughput rate is 44 hours, increasing to 54 hours when milling South Pipeline ore at 7500t/d. The CIC circuit consists of six carbon columns with a retention time of 18 minutes.

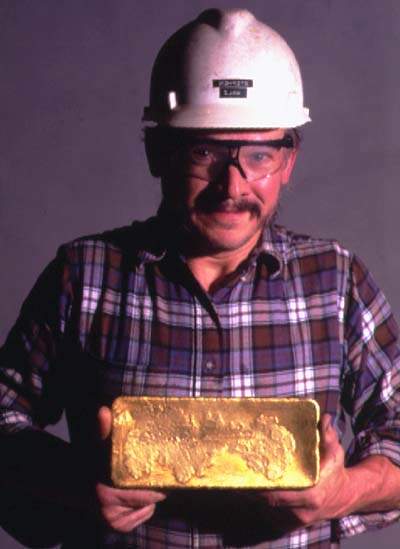

After stripping the carbon using a pressurised Zadra process, the gold is recovered by electrowinning on to stainless steel wool cathodes. The filter cake is dried, melted in an induction furnace and poured into doré bars assaying approximately 90–94% gold and 3–6% silver for shipping to commercial refineries.

Placer Dome’s share of 2004 production was treated as follows: 1.86Mt milled ore grading 5.4g/t gold went to carbon-in-leach processing, 20.79Mt at 0.7g/t was heap leached, and 254,000 tons of carbonaceous ore was sold.

Production

In 2005, the mine produced 904,000oz of gold, while production in 2006 fell to 444,000oz. In 2007-2008 average production was 500,000 ounces of gold annually. 3.25Mt of ore were milled in 2005 at a grade of 5g/t, as well as 23.1Mt at 0.58g/t being leached. In addition, the mine sold 277,000 tons of carbonaceous ore grading 7.3g/t for roasting and treatment at Barrick’s Goldstrike operation. The sharp reduction in output during 2006 resulted from lower-grade material being milled and leached.

Cortez Hills development

Construction of the Cortez Hills project, costing around US$500m, was expected to begin in mid-2007 once permitting has been completed. However, it wasn’t until 12 November 2008 that the Bureau Land Management approved a critical environmental impact statement which will now let mining commence.

The project is set to be the first simultaneous start-up of an underground and surface mine in Nevada. The underground mine is to begin production in the fourth quarter 2008, while the surface open-pit operation is planned to start-up in late 2009 or early 2010.

However, opponents of the Cortez Hills Gold Project, which include the Timbisha Shoshone Tribe, are seeking an immediate injunction saying that the mine will cause irreparable harm and prevent the Shoshone people from accessing areas that they use for religious purposes. This is despite the establishment of the first ever mining company/indigenous communities’ collaborative agreement which was signed by the leaders of four out of five Western Shoshone communities in Nevada.

It is expected that if the plans do go ahead, a further 100 positions will be added during 2009 and as part of the expansion Barrick is relocating a county road from Crescent Valley to the town of Eureka at a cost of $15m.