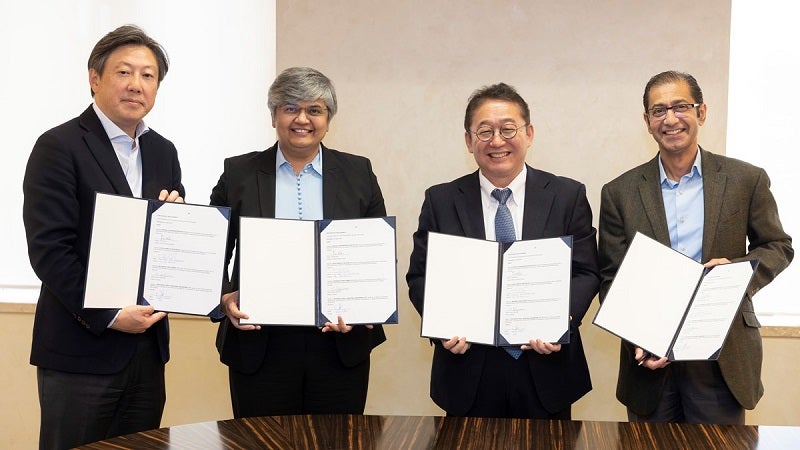

ArcelorMittal has joined forces with BHP, Mitsubishi Heavy Industries Engineering (MHIENG), and Mitsubishi Development to trial carbon capture technology at its steel plants in Belgium and North America.

Japan’s MHIENG has developed the technology to be used in the trial at ArcelorMittal’s steel blast furnace in Ghent, Belgium, and one of its Direct Reduced Iron (DRI) plants in North America.

BHP and Mitsubishi Development will fund this multi-year trial. The firms are the major suppliers of steel raw materials to ArcelorMittal’s operations in Europe.

The parties will also carry out a feasibility and design study to support full-scale deployment.

The partnership is aimed at identifying ways to enhance carbon capture and utilisation and/or storage (CCUS) technologies in the steelmaking sector, which as per Reuters is responsible for 7%-9% of global greenhouse gas (GHG) emissions.

The Ghent trial using MHIENG’s proprietary CCUS technology will involve two phases, with phase one helping separate and capture the CO₂ top gas from the blast furnace at a rate of nearly 300kg on a daily basis.

In phase two, tests will be conducted on the separating and capture of CO₂ from the off-gases in the hot strip mill reheating furnace that burns several industrial gases.

ArcelorMittal Gent intends to commission its Steelanol project later this year.

The project is a scale demonstration plant to capture carbon-rich process gases from the Gent blast furnace and convert them into ethanol.

This move is said to align with ArcelorMittal’s CO₂ emissions reduction goals of 35% by 2030 in Europe and 30% by 2030 globally.

ArcelorMittal Belgium CEO Manfred Van Vlierberghe said: “Alongside our continued energy efficiency improvements, we are developing two routes to decarbonise steelmaking: Smart Carbon and Innovative-DRI. Both routes will contribute to our journey to deliver carbon-neutral steelmaking.

“The Smart Carbon route also allows us to integrate carbon capture and re-use (CCU) or storage (CCS) technologies, capturing carbon emitted during the steelmaking process.”

Recently, ArcelorMittal South Africa collaborated with Sasol to explore green hydrogen usage for steel making.

BHP has also signed several partnerships in recent times for the production of green steel. This includes alliances with the University of Newcastle in Callaghan, Australia, as well as Tata Steel, among others.