Theta Gold Mines, an Australia-based gold mining company, plans to restart the historical underground gold mines at the Transvaal Gold Mining Estate (TGME) in Mpumalanga Province, South Africa.

The project plans to initially extract resources from the Beta (including the Beta North, Beta Central and Beta South sections), Rietfontein, Frankfort and Clewer-Dukes Hill-Morgenzon (CDM) mines, which hold a significant amount of underground gold resources.

The mines were not mined due to technological limitations or limiting ore characteristics. Theta Gold plans to develop up to 40 historical gold mines in the region.

Trial mining was conducted at Frankfort in December 2021 and a definitive feasibility study for the project was completed in July 2022. The project has an estimated life of mine (LoM) of 12.9 years producing 1.08 million ounces (Moz) of gold from 1.24Moz of mined gold and requires a capital investment of $174.3m.

Construction is expected to commence in December 2022, while first production is expected by the second quarter of 2024. Theta Gold aims to achieve a gold ore production rate of 160,000oz a year within five years in a phased manner.

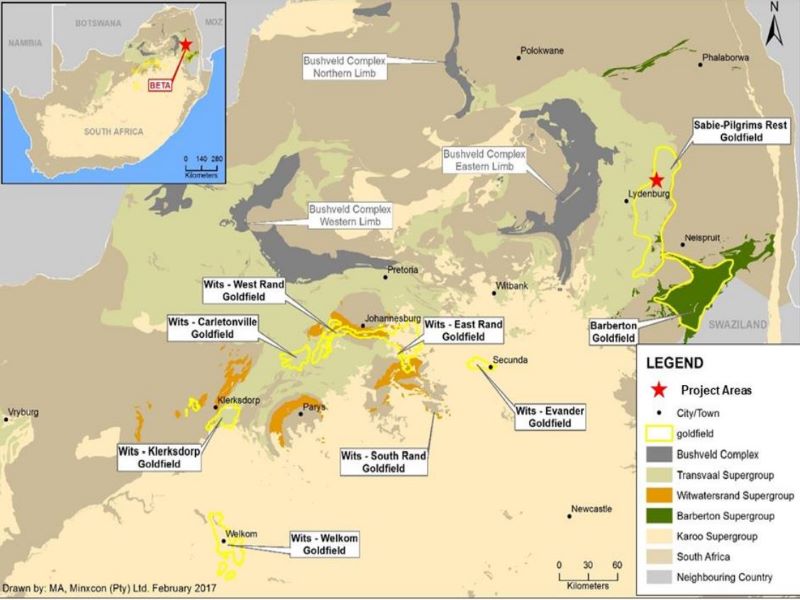

TGME Project location and geology

The TGME underground project is in the historically prolific gold mining region of Mpumalanga Province. The project is located approximately 370km north-east of Johannesburg and centred around the town of Pilgrims Rest.

The project lies within the Sabie-Pilgrims Rest Goldfield, which extends across 140km in a north-north-easterly direction, with a maximum width of 30km along the Great Escarpment of southern Africa. It holds more than 43 historical gold mines spread across an area of 620km².

Gold mineralisation is hosted in shear zones within the sedimentary host rocks of the Transvaal Supergroup.

Mineralisation and reserves of the TGME Project

The principal mineralisation at the TGME underground project occurs in concordant reefs in flat, parallel shears. The shears occur mainly on shear partings within the Malmani dolomites and the stratiform bodies are generally stratabound near the base of the units.

The proven and probable mineral reserves at the TGME underground project are estimated at 2.85Mt grading 6.09g/t of gold, with a total gold content of 558koz.

Mining methods at the Transvaal Gold Mining Estate

Mining operations are envisaged to commence at Beta followed by Rietfontein, which are higher-grade mines, followed by CDM and Frankfort simultaneously.

Mining operations at Beta, Frankfort and CDM are proposed to be carried out via mechanised long-hole drilling to narrow reef mining to selectively mine only the reef channel with minimal dilution.

The project will utilise existing mining infrastructure while adding new accesses, underground development, and pre-development of the mining grids at Beta, Frankfort and CDM. Early stoping will commence once the development of mining grids moves to an advanced stage to enable sufficient ground to be opened up before the planned stoping tonnes.

Conventional mining methods will be utilised at Rietfontein through shrinkage stoping with the use of hybrid loading methods, which include trackless load-haul dumpers (LHDs) and rail-bound locomotives. Existing audits and underground development will be used at Rietfontein with the addition of new development ends and declines, including the extension of an existing decline.

Upon commencement of underground development, the on-reef development will be stockpiled for a period of ten months prior to the commissioning of the processing plant due to low mining volume.

Gold ore processing capabilities

A new processing facility will be established on the site of a historical metallurgical plant, which is situated approximately 40km from the project site, to treat ore from the underground operations.

The processing infrastructure will be developed in three phases with each phase featuring a standalone processing facility in association with the mining plan of the ore body.

The first phase involves a 45,000 tonnes per month (tpm) oxide ore processing plant comprising crushing, milling, carbon-in-leach (CIL) and elution circuit to produce doré on site. It also includes a flash flotation stage to remove sulphide-associated material prior to cyanidation. The flotation mass pull will be combined with the concentrator product from phase two.

Phase two will involve a 20,000tpm gold concentration plant, including crushing, milling, dense media separation (DMS) and flotation circuits to produce a combined carbon and sulphide flotation concentrate.

Phase three will involve a 45,000tpm leach-ox process plant, including crushing, milling and carbon/sulphide flotation. The plant will consist of a gold concentrator plant and the CIL plant from phase one and phase two.

A dedicated CIL (CIL 3) circuit will process the carbon flotation concentrate while sulphide flotation concentrate will be oxidised with liquid oxygen and high shear reactors under atmospheric conditions.

The oxidised product will be treated in separate batches at CIL 1 while the tails will be treated in CIL 2 to enable on-site doré production from all recovered gold with no concentrate produced.

The phase one plant will be constructed first to treat CDM, Rietfontein and Beta ore, while phase three will be developed prior to the commencement of mining at Frankfort.

Sustainability features in South Africa

South Africa has been at the forefront in the development and implementation of environmental, social and governance initiatives (ESG). Theta Gold has taken initiatives to reduce carbon emissions from the project by designing infrastructure layouts that can be placed on already disturbed footprints, thereby avoiding the need to clear new vegetation.

Contractors involved

The feasibility study was completed by Theta Gold Mines’ technical team, along with independent consultant Minxcon. The latter also provided the mineral resource estimates for the project as of February 2021.

Engineering company Met63 was contracted to provide a detailed design for the processing plant.

Paterson & Cooke Consulting Engineers (Paterson & Cooke) was engaged for a pre-feasibility study (PFS) report on the underground deposition of tailings material.

Mining services provider Digmin was contracted for the trial mining operations at the project.