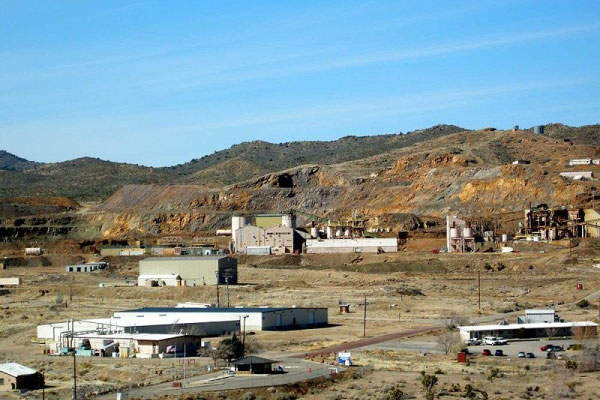

Molycorp is currently modernising its Mountain Pass rare earth elements (REE) mine in California, which is the only active rare earth operations facility in the US.

Underway since 2011, the $1.25bn modernisation project titled Project Phoenix involves construction of an advanced manufacturing facility for producing rare earth concentrate from Mountain Pass ore. Upon completion, the mine is set to be one of the world’s biggest producers of rare earths.

Mining activities at the historic Mountain Pass mine began again in December 2010. Construction of the new manufacturing facility started in January 2011 and the first phase was commissioned in January 2013. The second phase expansion, approved in 2011, has a cost projection of $250m.

Approximately 700 construction jobs and 200 to 300 permanent operational positions will be created by the project.

Details of Project Phoenix rare earth manufacturing facility

Part of the Mother Lode gold belt in Amador County of the state of California, US.

The Project Phoenix facility obtained final environmental permit for construction in December 2010. It is being developed in two phases, with the first targeting an annual production of 19,050t of rare earth oxide equivalent (REO), with the second phase targeting to increase it to 40,000t a year.

Minerals are extracted to produce rare earth concentrates and oxides such as lanthanum, cerium, neodymium, praseodymium, and yttrium. The facility is also expected to produce heavy rare earth concentrates such as samarium and europium, as well as rare earth-based water treatment products called SorbXTM.

In addition, the new facility consists of a new chlor-alkali plant, which was commissioned in March 2014 and recycles wastewater from Mountain Pass operations and produces chemical reagents to be used in rare earth production.

The new facility provides rare earth feedstock for the company’s processing plants at Sillamäe in Estonia, Zibo and Jiangyin in China, and Tolleson in Arizona.

Mountain Pass mine history, location, geology, and reserves

The rare earth mine was discovered in 1949 and the mining claims were sold to Molybdenum Corporation of America in 1952. Large-scale mining was conducted between 1965 and 1995.

Unfavourable prices and environmental restrictions lead to the closure of the mine in 2002. The property was acquired by Chevron from Unocal Corporation in 2005 and was in-turn sold it to Molycorp Minerals in 2008.

The rare-earth deposit is located on the southern portion of the Clark Mountain Range. The deposit occurs a block of metamorphic rocks belonging to the pre-Cambrian age, and is four to five miles wide, extending approximately 18 miles long in north-north-west direction. This metamorphic complex is surrounded on the south and east by the alluvium of Ivanpah Valley, and by faults on the east and west sides.

As of April 2012, the proven and probable rare earth ore reserves of Mountain Pass mine were estimated to be 18.4mt, at a cut-off grade of 5%. The mine was estimated to contain approximately 2.94 billion pounds (1.3mt) of rare earth oxide equivalent.

Mining and processing

Ore extracted from the mine using traditional open-pit mining methods is crushed into gravel sized pieces to separate bastnasite and monazite rare earth containing minerals from the rest of the material. Crushed pieces are then grinded and separated using flotation separation process, involving addition of an agent.

Obtained material is chemically treated using hydrochloric acid, which allows the rare earth elements to dissolve. The resultant concentrate is further chemically treated in order to separate the rare earth elements from the concentrate at a purity of 99.9% or greater.

Construction and infrastructure facilities at Mountain Pass mine

The major facilities constructed under the Project Phoenix include an advanced paste storage facility, a paste facility plant, a new crushing facility, a cracking facility, and a reclaimed tailings storage facility.

Electrical power and steam required for the mine and the Project Phoenix facility is being sourced from the on-site combined heat and power (CHP) plant. Natural gas for the CHP plant is sourced from a lateral supply line connecting the facility to a nearby interstate natural gas pipeline operated by Kern River Gas Transmission Company.

Production and sale agreements

The Mountain Pass mine recorded 1,111t of REO production during the first quarter of 2014. A joint venture called Intermetallics Japan, IMJ, was formed in November 2011 with Daido Steel and Mitsubishi to manufacture and sell the neodymium magnet (NdFeB) produced at the facility. It is also sold via Molycorp’s downstream operations under the Molycorp Magnequench brand at its wholly owned manufacturing facilities in Tianjin, China and Korat, Thailand.

A supply contract was also signed with W R Grace in November 2010 to supply REOs from the Mountain Pass facility, mainly lanthanum concentrate, through mid-2012. Another contract was signed to supply approximately 75% of the annual lanthanum production to Grace for a three-year period upon achieving the expected annual production rates.

Contractors involved

SRK Consulting conducted the rare earth reserves estimation for the mine.